ARapidPrototype Laser Cutting Service

Benefit from our exceptional manufacturing capabilities and over a decade of industry expertise at ARapidPrototype. We deliver top-notch custom laser cutting services with unparalleled quality and outstanding results potential. Our team of highly skilled machinists harness cutting-edge laser cutting facilities to tackle a wide range of materials, from delicate aluminum foils to thick steel sheets. Explore our metal laser cutting service featuring advanced processes and technology for your projects.

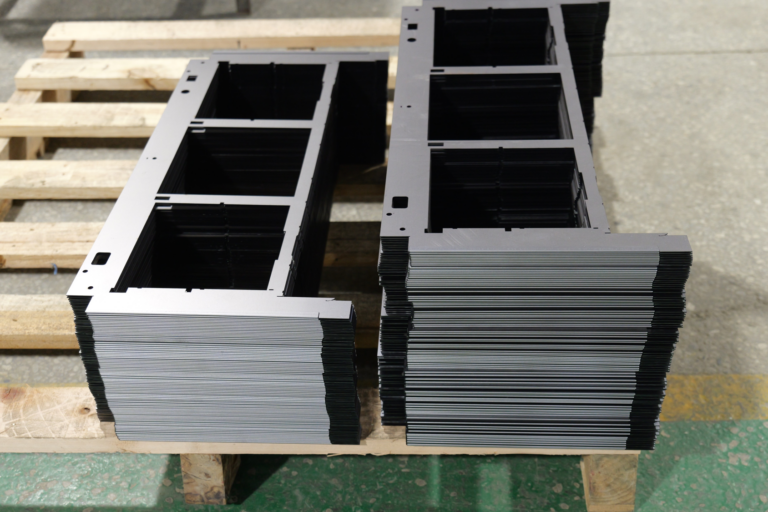

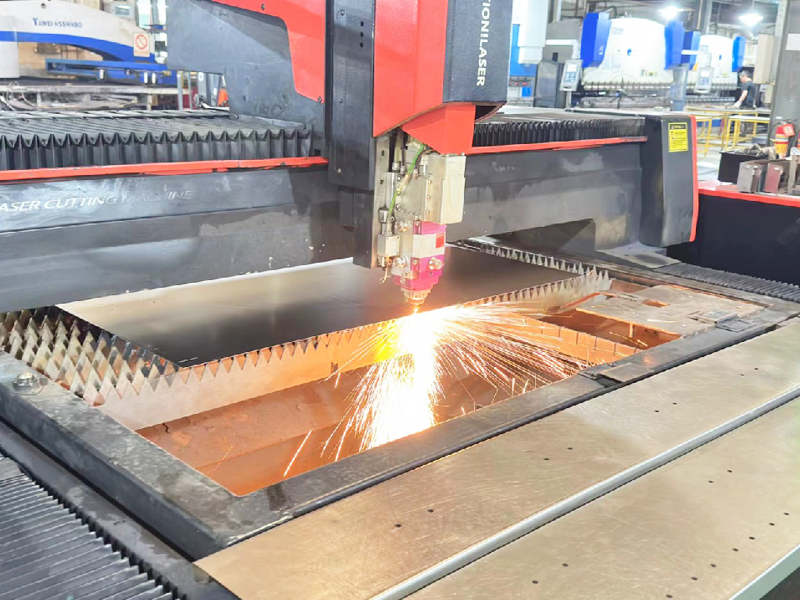

Fiber Laser Cutting

It’s a process that utilizes a fiber laser for cutting. In this process, the fiber laser transmits the laser beam to the cutting head through fiber optics, where it is focused onto the surface of the workpiece to perform cutting with high energy density. Fiber laser cutting is characterized by its high speed, precision, efficiency, and versatility across various materials, making it widely used in industrial manufacturing for metals, non-metals, and composite materials alike.

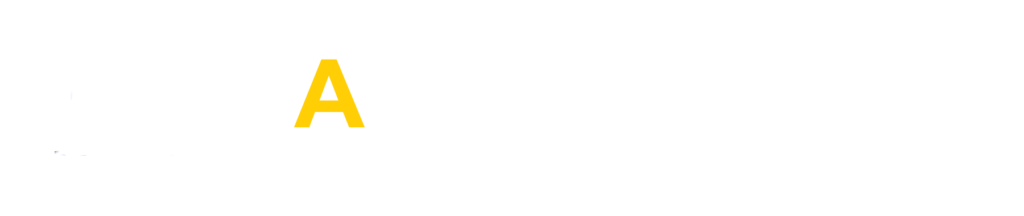

ARapidPrototype Laser Cutting Parts

For many years, ARapidPrototype laser cutting service has covered a wide range of applications for many industries. Below are some of our previous laser cutting projects.

Laser Cutting Design Guidelines

Adhere to these standards for flat laser-cut components to enhance quality and expedite production timelines.

| Maximum Size | 1220x2440mm |

| Material Thicknesses | 1mm to 6mm |

| Tolerances | Plus or minus 0.1mm for normal features; Plus or minus0.05mm for insert holes. |

Materials and Thicknesses for Laser Cut Parts

We offer the following metal materials for custom laser cut parts. Note that based on material thickness, maximum part size will vary.

| Material | Grade | Thicknesses Available |

| Aluminum |

| 0.025 in. – 0.250 in. (0.635mm – 6.35mm) |

| Steel |

| 0.025 in. – 0.250 in. (0.635mm – 6.35mm) |

| Stainless Steel |

| 0.025 in. – 0.250 in. (0.635mm – 6.35mm) |

| Copper |

| 0.025 in – 0.125 in. (0.635mm – 3.175) |

| Brass |

| 0.025 in. – 0.125 in. (0.635mm – 3.175) |

Applications for Laser Cut Parts

Laser cutting of parts is a prevalent manufacturing method employed across industries like energy storage, computer electronics, robotics, and aerospace. Typical components produced through this method encompass:

- Flat parts: Laser cutting is suitable for cutting flat parts such as sheets, panels, and bases.

- Geometric shapes: Laser cutting can accurately cut various geometric shapes, including rectangles, circles, ellipses, and polygons.

- Holes and cutouts: Laser cutting can easily cut holes and cutouts for connecting or assembling parts.

- Engraving and marking: Laser cutting can also be used to engrave or mark on the surface of parts for identification, traceability, or decorative purposes.

- Bending and folding: While laser cutting is primarily used for flat parts, it can be used to pre-cut parts for subsequent bending or folding into the desired shapes.

Fast Online Quotation

Simply upload your design files and select material, finishing options, and lead time. Get rapid quotes for your sheet metal components in just a few clicks.

Robust Manufacturing Capacity

Our domestic factories in China provide comprehensive sheet metal project solutions, offering flexible material options, diverse surface finishes, and unlimited manufacturing capacity for both low and high volume production runs.

Guaranteed Quality

With an ISO 9001:2015 certified sheet metal manufacturing facility, we offer material and full dimensional inspection reports upon request. Trust that the parts you receive from ARapidPrototype will surpass your expectations.

Sheet Metal Engineering Support

We provide 24/7 online engineering customer support for your custom sheet metal engineering and manufacturing problems. This includes case-by-case suggestions to help you reduce costs early on in the design phase.

The ARapidPrototype Pocess

Step 1

Upload Your Design

It takes just seconds to upload your design files to the quote form. We benchmark a minimum of 3 quotes from trusted partners and deliver you the best price within one business day.

Step 2

Step 3

Step 4

ARapidPrototype Laser Cutting Service FAQs

Our laser cutting process is compatible with a wide variety of materials, including ferrous and non-ferrous metals, plastics, and other non-metals. We can also cut materials with varying weights, thicknesses, and mechanical properties.

Our laser cutting service can cut material with a precision of +/- 0.002 inches and a positional accuracy of +/- 0.004 inches.

ARapidPrototype has different thickness specifications for different laser cutting materials. The maximum thickness for stainless steel and aluminum is < 15 mm. On the other hand, we can cut carbon steel up to 25 mm thick and less than 12.7 mm for copper.

Yes, our experts have adequate experience and knowledge of laser engraving and etching. Therefore, we are able to provide superior quality services that will meet your demands.

Yes, you can bend the material with the various bending techniques offered at ARapidPrototype. There is an allowance for bending in your flat pattern profiles. We offer sheet metal bending techniques like V-bending, roll bending, rotary bending, wipe bending, and so on. The technique used will depend on your specific applications.

Join ARapidprototype on the path to better, faster

and stronger innovation

Get A Quote NowAll uploads are secure and confidential.