ARapidPrototype

On-Demand Prototyping & Manufacturing Services in China

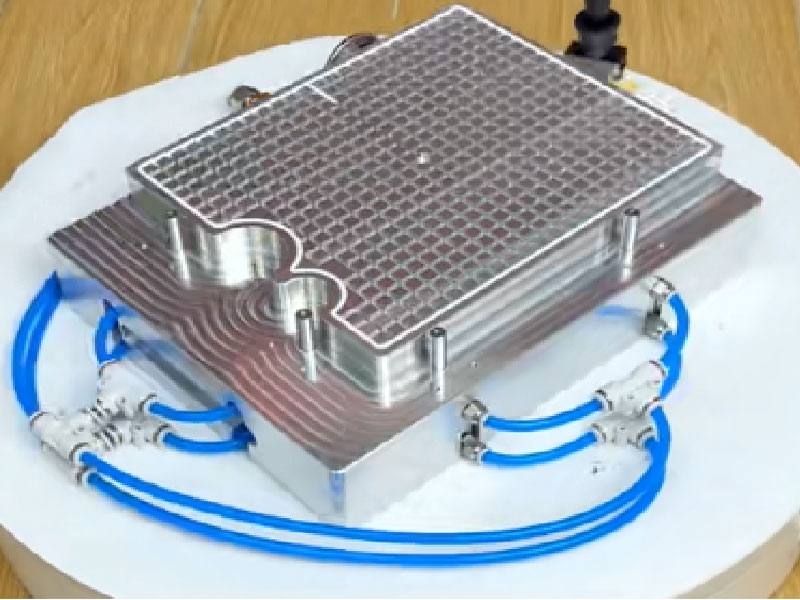

- On-demand one-stop service providing CNC milling, CNC turning, EDM high-precision machining, grinding, and related surface treatments.

- Providing various 3D printing rapid prototyping services, including SLA, SLM, SLS, and FDM.

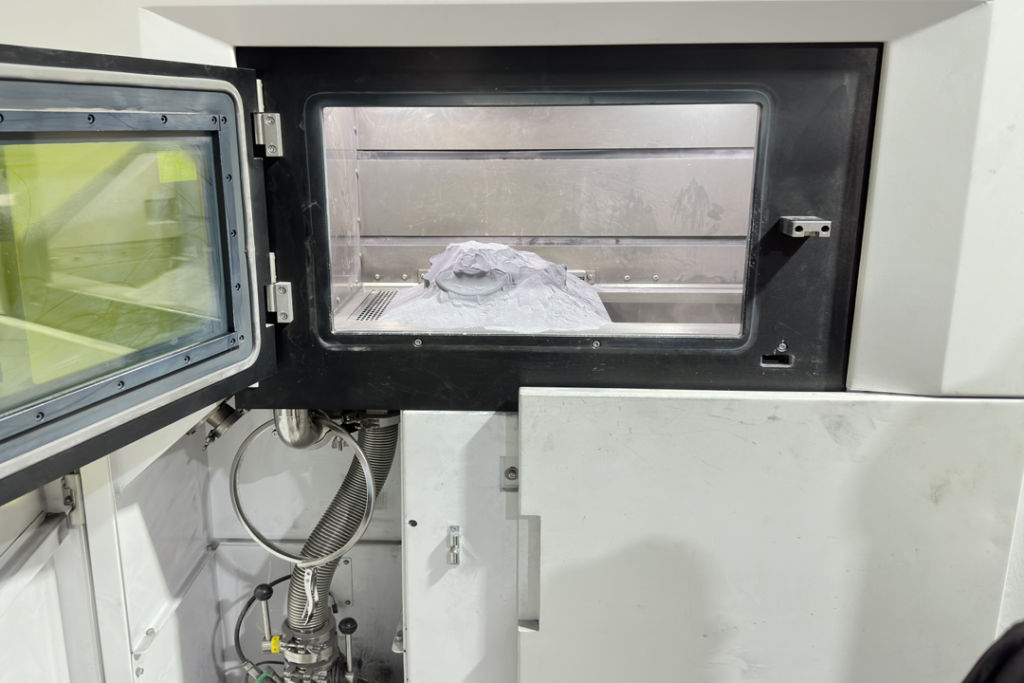

- Silicone mold making and rapid mold production in various sizes, including surface treatments.

- Large-scale, stable sheet metal processing services, covering the entire process and surface treatments.

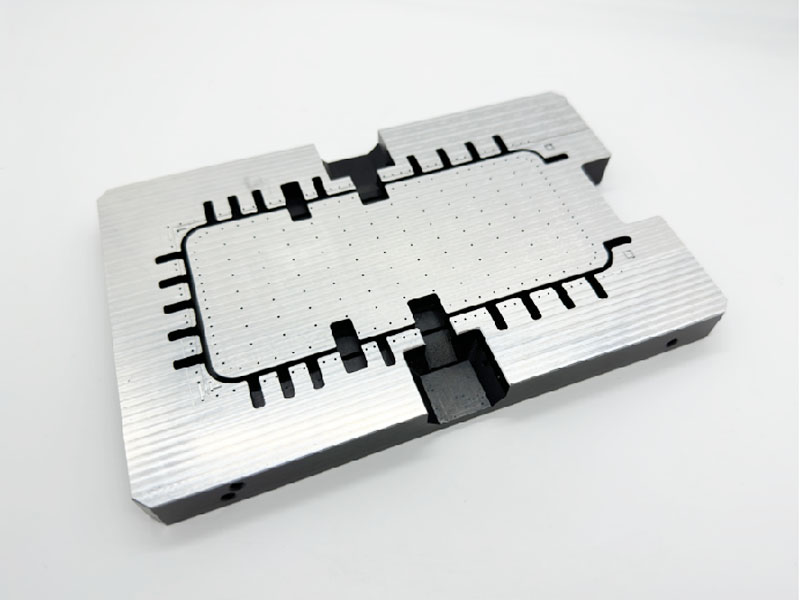

- Dedicated to the design and production of jigs for 3C products, serving testing and production processes.