ARapidPrototype

Why choose us to customize IC test fixtures

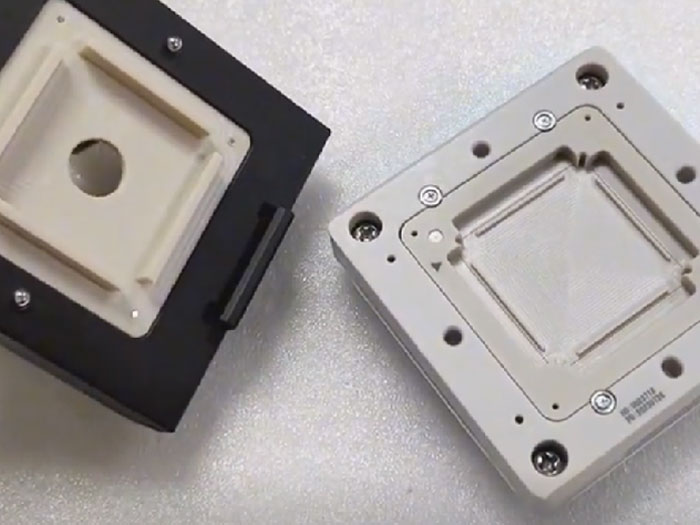

ARapidPrototype IC Test Fixture

IC Test Jigs Fixture ARapidPrototype

IC Test Jigs Fixture ARapidPrototype

IC Test Jigs Fixture ARapidPrototype

IC Test Jigs Fixture ARapidPrototype

IC Test Jigs Fixture ARapidPrototype

IC Test Jigs Fixture ARapidPrototype

What Is IC Test Fixture?

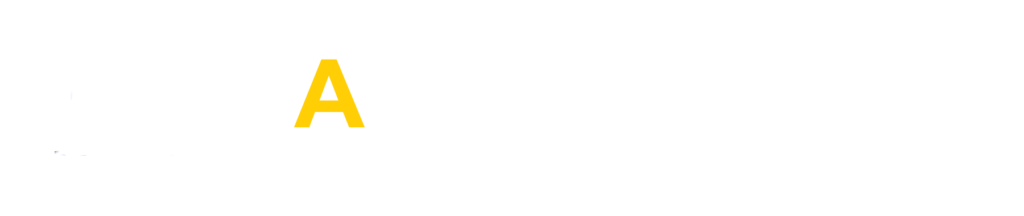

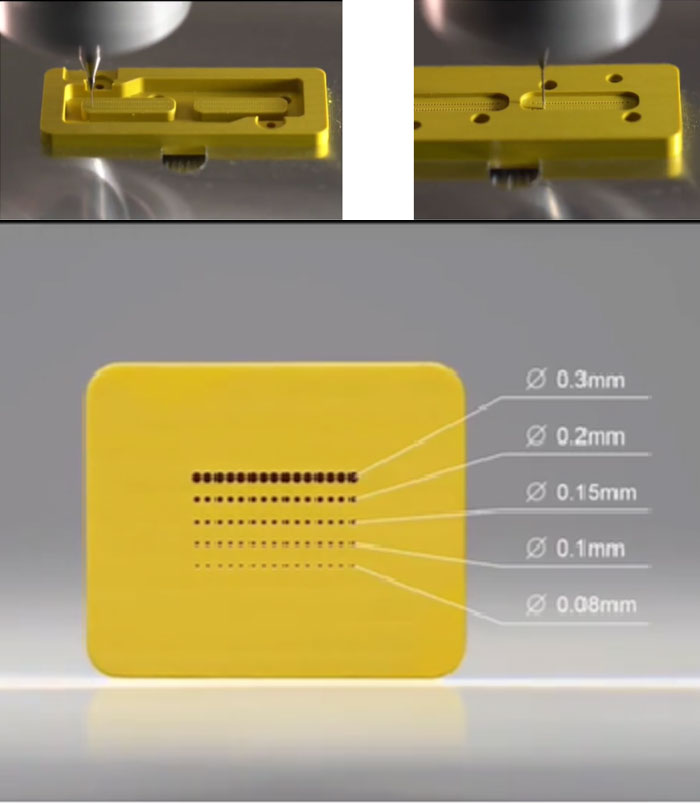

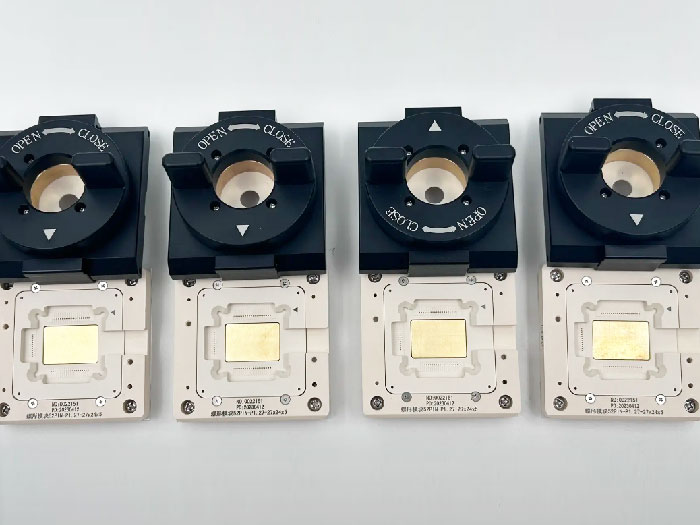

IC test fixtures are specialized tools designed for precise and reliable testing of integrated circuits (ICs). We offer a range of fixtures, including Test Socket, Multi-Port, Automated, Simulation, Analytical, and Measurement fixtures, capable of high-speed testing up to 150mm/sec. With a high precision design of ±0.002″ and a single-sided pin layout, our fixtures can handle ICs with a pitch of 1.2mm and accommodate sizes from 40x50mm to 510x508mm, along with circuit boards up to 6mm thick. All fixtures are customizable, providing anti-static protection and optimizing signal transmission to ensure efficient and accurate testing. This flexibility and performance give us a unique advantage in meeting diverse testing needs.

IC Test Fixture Categories, Material Choices

Typical Precision, and Industry Applications

| Category | Description | Material Choices | Typical Precision | Industry Applications |

|---|---|---|---|---|

| Bed of Nails Test Fixtures | Suitable for mass production testing, providing high-density contact points, ideal for testing multi-pin ICs | Aluminum Alloy, Stainless Steel, Brass | Geometric Tolerance: ±0.01mm, High Precision: ±0.005mm | Consumer Electronics, Automotive |

| Probe Card Fixtures | Mainly used for wafer testing, featuring high-precision micro-probes, suitable for fine IC pin testing | Aluminum Alloy, Stainless Steel, Brass | Geometric Tolerance: ±0.01mm, High Precision: ±0.005mm | Semiconductor, Microelectronics |

| Functional Test Fixtures | Used for testing the functional characteristics of ICs, including analog and digital test interfaces, suitable for various testing needs | Aluminum Alloy, Stainless Steel, Engineering Plastics (POM, PEEK) | Geometric Tolerance: ±0.01mm, High Precision: ±0.005mm | Telecommunications, Aerospace |

| Programming Fixtures | Used for firmware programming and testing of ICs, suitable for programmable ICs like microcontrollers and memory chips | Aluminum Alloy, Stainless Steel, Engineering Plastics (POM, PEEK) | Geometric Tolerance: ±0.01mm, High Precision: ±0.005mm | Computing, IoT Devices |

| Pneumatic Fixtures | Uses pneumatic clamping, suitable for scenarios requiring quick change of test objects | Aluminum Alloy, Stainless Steel, Brass, Engineering Plastics (POM, PEEK) | Geometric Tolerance: ±0.01mm, High Precision: ±0.005mm | Medical Devices, Industrial Equ |

The ARapidPrototype Pocess

Step 1

Upload Your Design

It takes just seconds to upload your design files to the quote form. We benchmark a minimum of 3 quotes from trusted partners and deliver you the best price within one business day.

Step 2

Step 3

Step 4

IC Test Jigs and Fixture FAQs

An IC test jig or fixture is a specialized tool designed to hold and connect integrated circuits (ICs) during testing, ensuring accurate electrical connections. High-quality fixtures can achieve positioning tolerances of ±0.002 inches for precise testing.

- Test Socket Fixtures: For various IC packages.

- Multi-Port Test Fixtures: Allow multiple connections simultaneously.

- Automated Test Fixtures: Designed for high-speed, automated testing.

- Simulation Fixtures: Used for simulating different operational conditions.

- Analytical Fixtures: For in-depth analysis of IC performance.

- Measurement Fixtures: Focused on precise measurements.

IC test fixtures improve testing accuracy, repeatability, and efficiency, reducing setup time by up to 30% and minimizing the risk of damage to sensitive components.

Consider factors such as IC pitch (typically ranging from 0.4 mm to 1.5 mm), size (from 40×50 mm to 510×508 mm), board thickness (up to 6 mm), and specific testing requirements like speed and precision.

Yes, manufacturers often provide customization options to fit specific IC sizes and layouts. Customization can include material selection and special design features to meet unique testing needs.

The lifespan of quality fixtures can exceed 3000 test cycles while maintaining over 95% performance stability, depending on usage and material quality.

Join arapidprototype on the path to better, faster

and stronger innovation

Get A Quote NowAll uploads are secure and confidential.