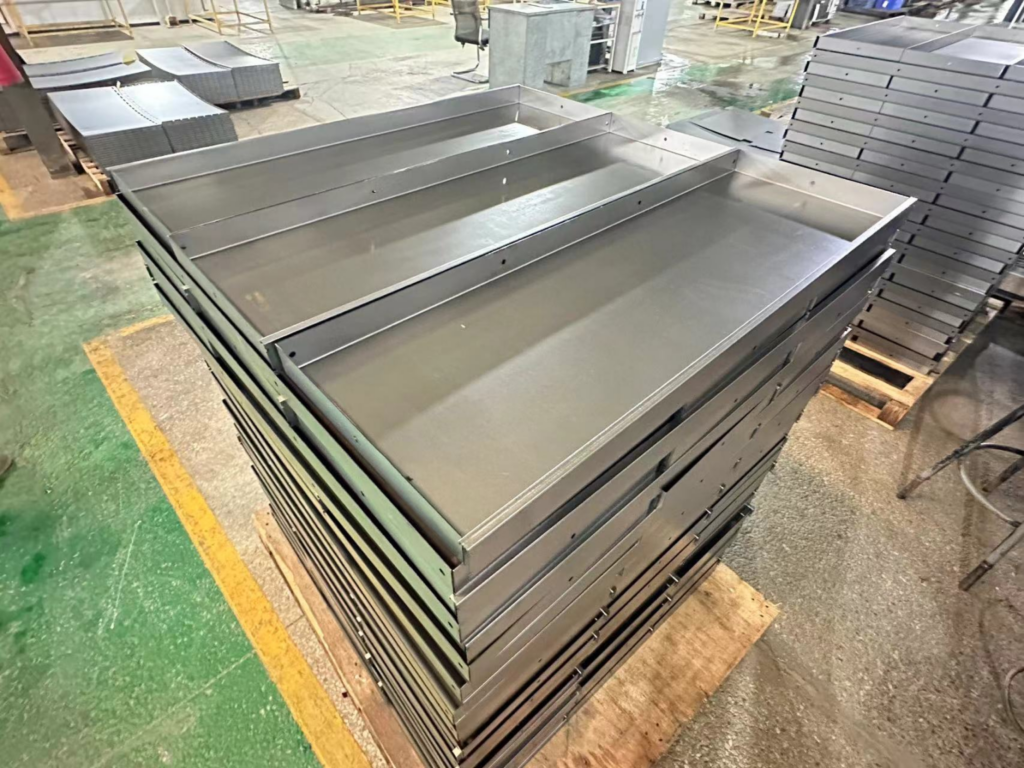

UNPrototype rapide

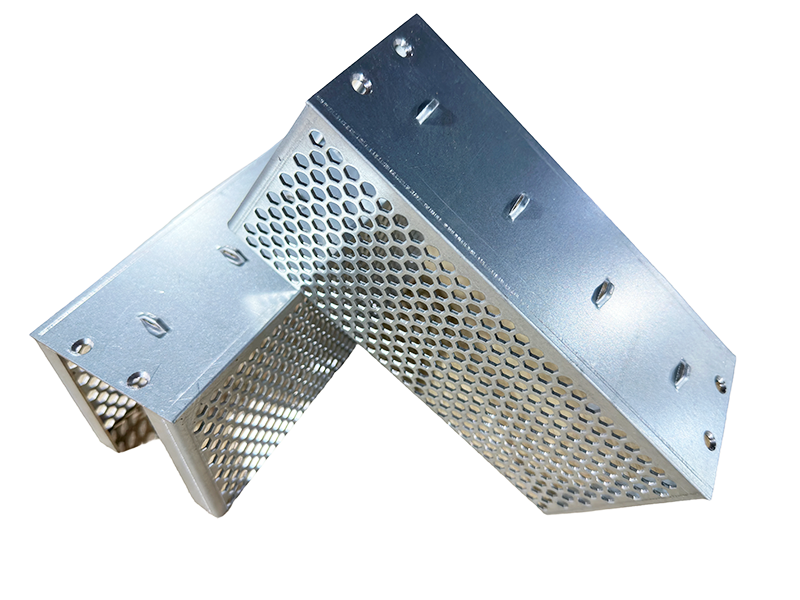

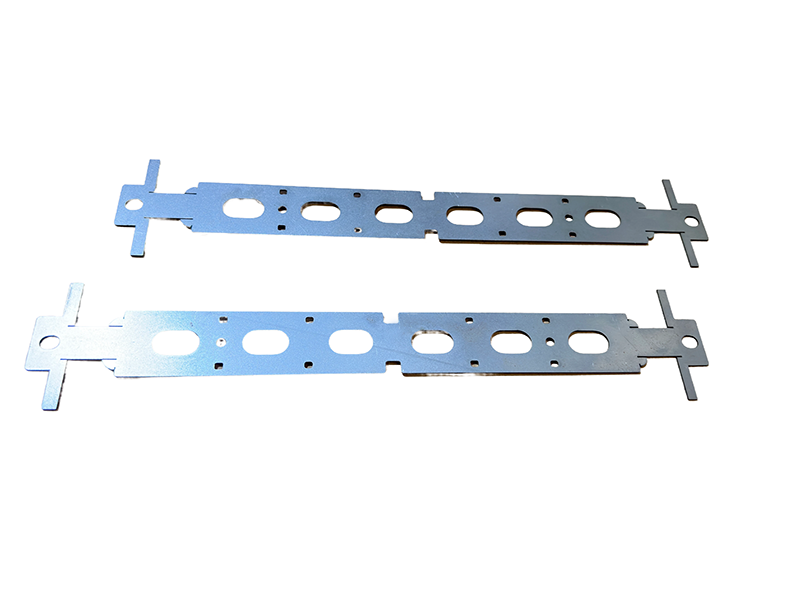

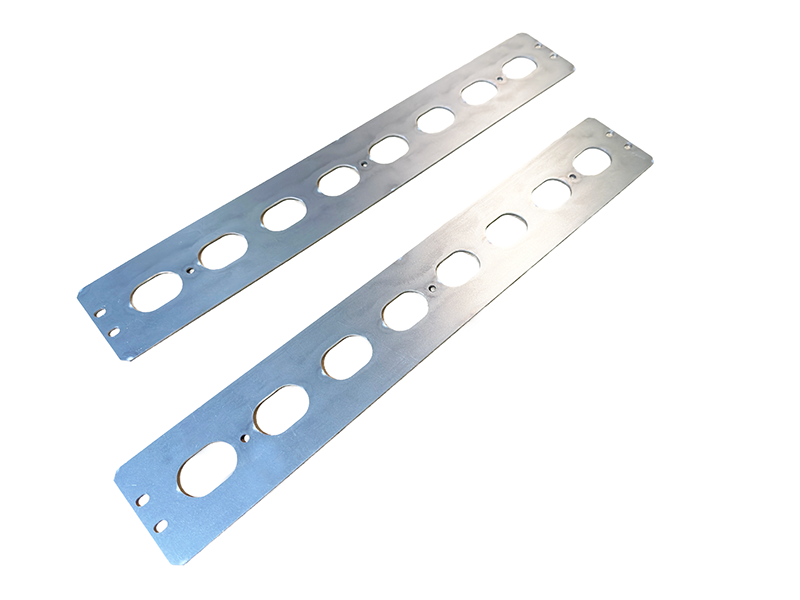

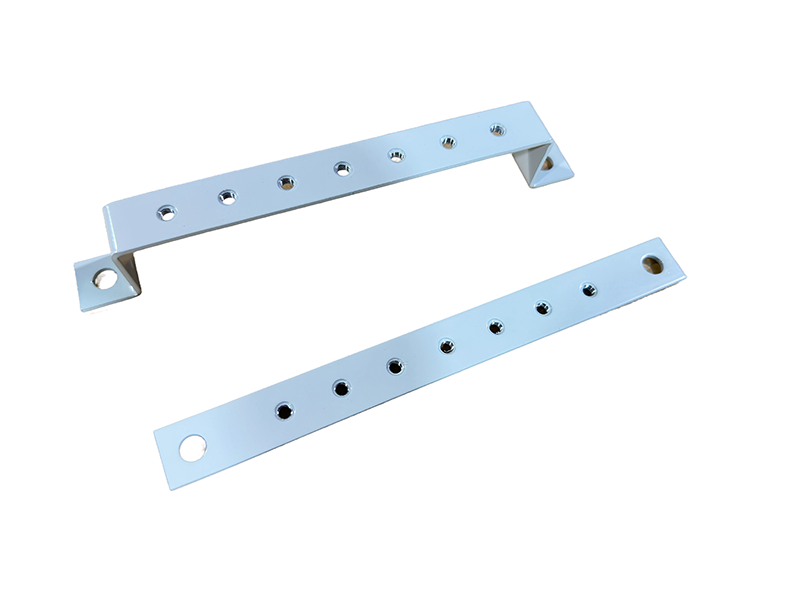

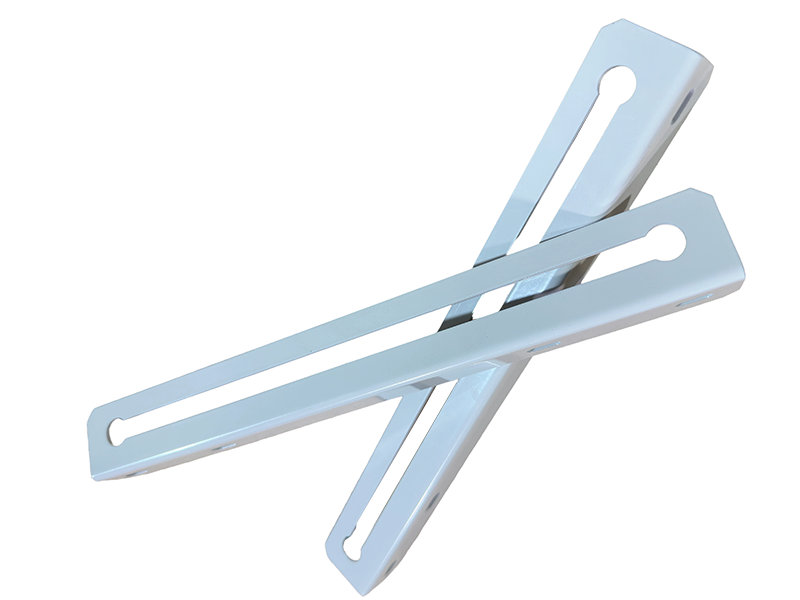

Service de fabrication de tôle

- Capacités de découpe de tôle allant de 0,5 mm à 5 mm d'épaisseur. (La capacité de coupe du réseau atteint 10 mm.)

- Une sélection de plus de 10 matériaux et finitions. (revêtement en poudre, polissage de surface, miroir, polissage, PVD…etc)

- Notre délai de livraison le plus rapide de seulement 3 jours ouvrables.