ARapidePrototype

Pourquoi nous choisir pour personnaliser les montages de test de circuits intégrés

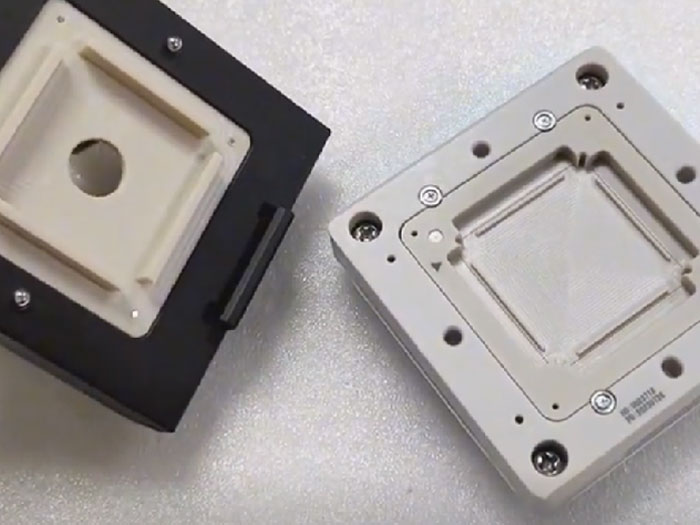

Dispositif de test de circuit intégré ARapidPrototype

Dispositif de test de circuits intégrés ARapidPrototype

Dispositif de test de circuits intégrés ARapidPrototype

Dispositif de test de circuits intégrés ARapidPrototype

Dispositif de test de circuits intégrés ARapidPrototype

Dispositif de test de circuits intégrés ARapidPrototype

Dispositif de test de circuits intégrés ARapidPrototype

Qu'est-ce qu'un dispositif de test IC ?

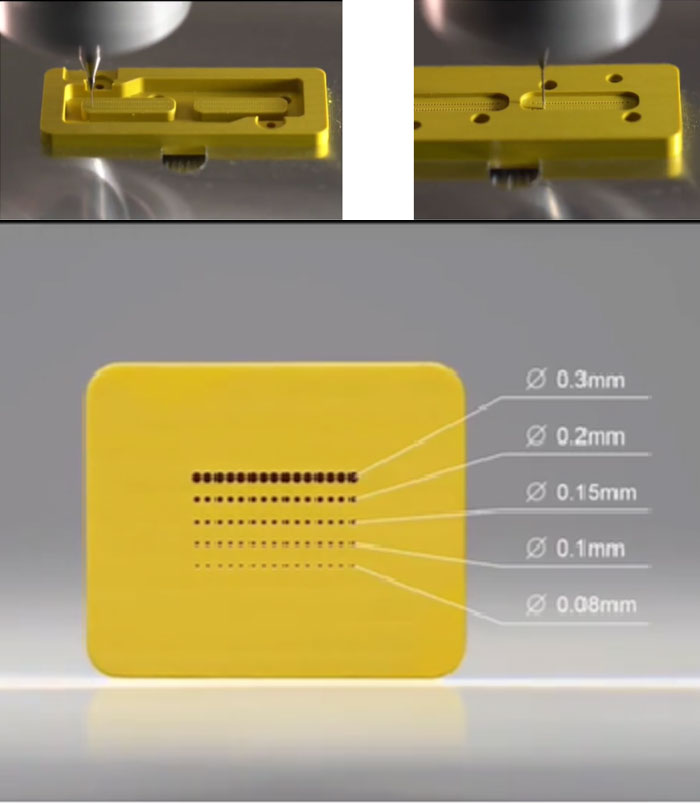

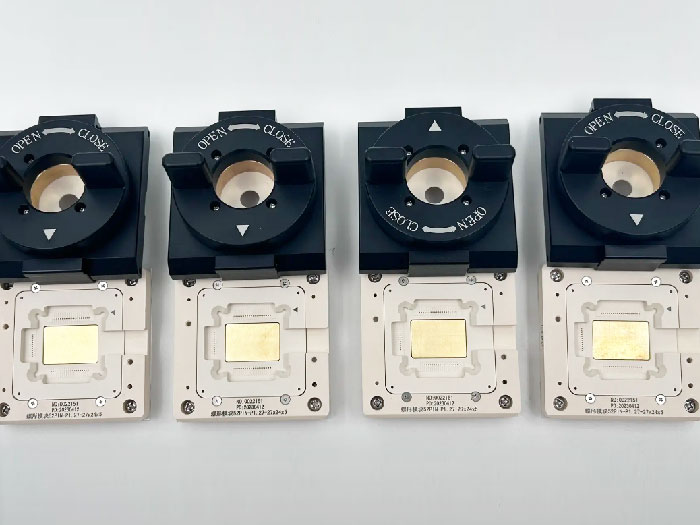

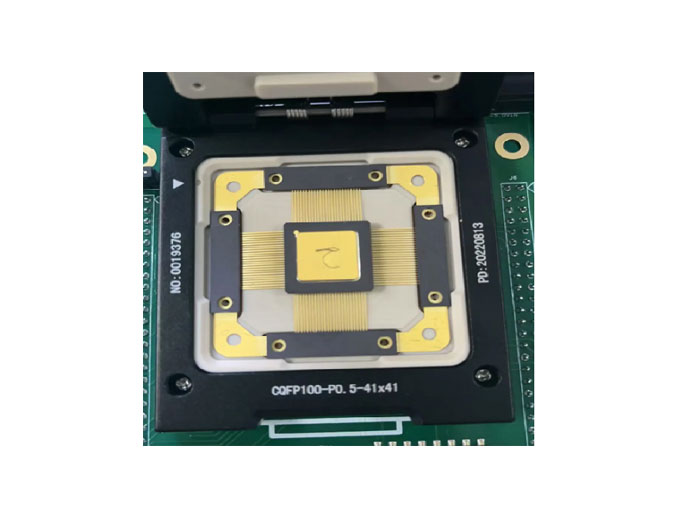

Les montages de test pour circuits intégrés (CI) sont des outils spécialisés conçus pour des tests précis et fiables des circuits intégrés (CI). Nous proposons une gamme de montages, notamment des supports de test, des montages multiports, des montages automatisés, de simulation, d'analyse et de mesure, capables de réaliser des tests à grande vitesse jusqu'à 150 mm/s. Grâce à une conception haute précision de ± 0,002″ et à un brochage unilatéral, nos montages acceptent des CI au pas de 1,2 mm et des tailles allant de 40 x 50 mm à 510 x 508 mm, ainsi que des circuits imprimés jusqu'à 6 mm d'épaisseur. Tous les montages sont personnalisables, offrant une protection antistatique et optimisant la transmission du signal pour des tests efficaces et précis. Cette flexibilité et ces performances nous confèrent un avantage unique pour répondre à divers besoins de test.

Catégories de dispositifs de test de circuits intégrés, choix de matériaux

Précision typique et applications industrielles

| Catégorie | Description | Choix des matériaux | Précision typique | Applications industrielles |

|---|---|---|---|---|

| Dispositifs d'essai de lit de clous | Convient aux tests de production de masse, fournissant des points de contact haute densité, idéal pour tester les circuits intégrés multibroches | Alliage d'aluminium, acier inoxydable, laiton | Tolérance géométrique : ± 0,01 mm, haute précision : ± 0,005 mm | Électronique grand public, automobile |

| Fixations de cartes de sonde | Principalement utilisé pour les tests de plaquettes, doté de micro-sondes de haute précision, adaptées aux tests de broches de circuits intégrés fins | Alliage d'aluminium, acier inoxydable, laiton | Tolérance géométrique : ± 0,01 mm, haute précision : ± 0,005 mm | Semi-conducteur, microélectronique |

| Dispositifs de test fonctionnels | Utilisé pour tester les caractéristiques fonctionnelles des circuits intégrés, y compris les interfaces de test analogiques et numériques, adapté à divers besoins de test | Alliage d'aluminium, acier inoxydable, plastiques techniques (POM, PEEK) | Tolérance géométrique : ± 0,01 mm, haute précision : ± 0,005 mm | Télécommunications, aérospatiale |

| Appareils de programmation | Utilisé pour la programmation du micrologiciel et le test des circuits intégrés, adapté aux circuits intégrés programmables tels que les microcontrôleurs et les puces de mémoire | Alliage d'aluminium, acier inoxydable, plastiques techniques (POM, PEEK) | Tolérance géométrique : ± 0,01 mm, haute précision : ± 0,005 mm | Informatique, appareils IoT |

| Fixations pneumatiques | Utilise un serrage pneumatique, adapté aux scénarios nécessitant un changement rapide des objets de test | Alliage d'aluminium, acier inoxydable, laiton, plastiques techniques (POM, PEEK) | Tolérance géométrique : ± 0,01 mm, haute précision : ± 0,005 mm | Dispositifs médicaux, équipements industriels |

Le processus ARapidPrototype

Étape 1

Téléchargez votre conception

Il ne faut que quelques secondes pour télécharger vos fichiers de conception dans le formulaire de devis. Nous évaluons au moins 3 devis de partenaires de confiance et vous proposons le meilleur prix dans un délai d'un jour ouvrable.

Étape 2

Étape 3

Étape 4

FAQ sur les gabarits et dispositifs de test de circuits intégrés

Un dispositif de test de circuits intégrés (CI) est un outil spécialisé conçu pour maintenir et connecter les circuits intégrés (CI) pendant les tests, garantissant ainsi des connexions électriques précises. Les dispositifs de haute qualité permettent des tolérances de positionnement de ± 0,002 pouce pour des tests précis.

- Supports de test:Pour divers boîtiers IC.

- Dispositifs de test multiports: Autoriser plusieurs connexions simultanément.

- Dispositifs de test automatisés:Conçu pour les tests automatisés à grande vitesse.

- Montages de simulation:Utilisé pour simuler différentes conditions opérationnelles.

- Appareils d'analyse:Pour une analyse approfondie des performances du CI.

- Appareils de mesure:Axé sur des mesures précises.

Les montages de test IC améliorent la précision, la répétabilité et l'efficacité des tests, réduisant le temps de configuration jusqu'à 30% et minimisant le risque d'endommagement des composants sensibles.

Tenez compte de facteurs tels que le pas du circuit intégré (généralement compris entre 0,4 mm et 1,5 mm), la taille (de 40 × 50 mm à 510 × 508 mm), l’épaisseur de la carte (jusqu’à 6 mm) et les exigences de test spécifiques telles que la vitesse et la précision.

Oui, les fabricants proposent souvent des options de personnalisation adaptées à des tailles et configurations de circuits intégrés spécifiques. La personnalisation peut inclure le choix des matériaux et des caractéristiques de conception spécifiques pour répondre à des besoins de test spécifiques.

La durée de vie des luminaires de qualité peut dépasser 3 000 cycles de test tout en maintenant une stabilité de performance supérieure à 95%, en fonction de l'utilisation et de la qualité du matériau.

Rejoignez arapidprototype sur la voie vers un monde meilleur et plus rapide

et une innovation plus forte

Obtenez un devis maintenantTous les téléchargements sont sécurisés et confidentiels.