UNPrototype rapide

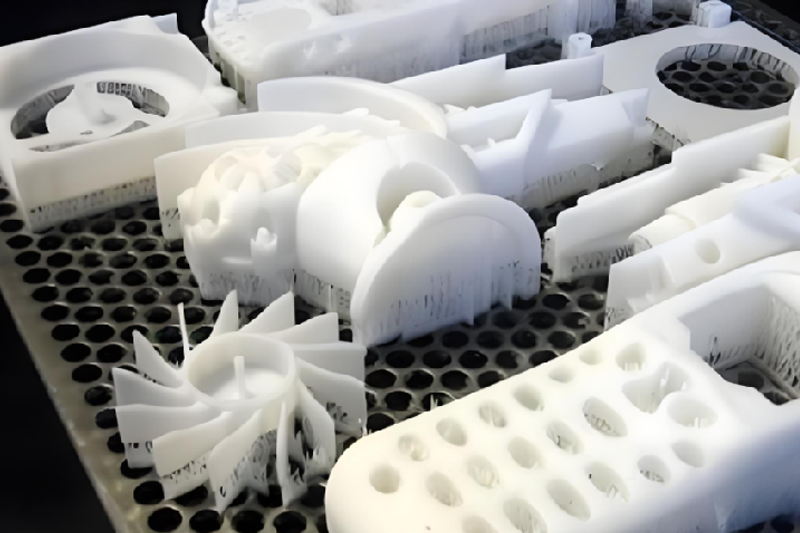

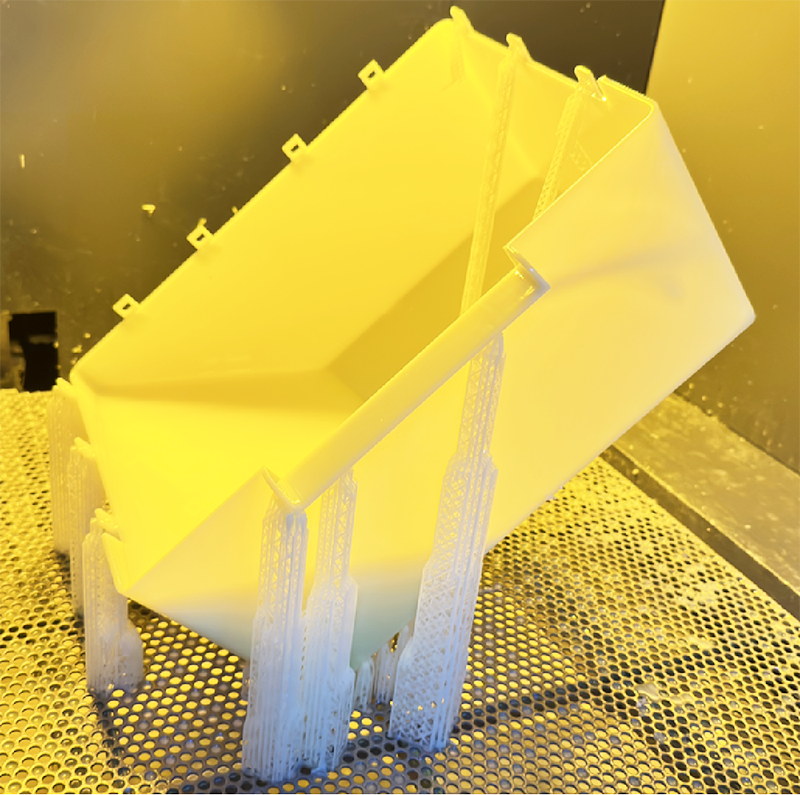

Services d'impression 3D SLA

- Notre vaste sélection comprend une pléthore de matériaux de prototypage et de résine industrielle, nous permettant de fabriquer des pièces en une seule journée.

- Capable d'accueillir des pièces nécessitant une précision exceptionnelle et des caractéristiques aussi minuscules que 0,005 (0,13 mm) pouces,

- Notre service garantit une qualité de surface supérieure, idéale pour les prototypes cosmétiques et les tests de forme et d'ajustement.