UNPrototype rapide

Services d'impression 3D

- Pièces imprimées en 3D en seulement 3 jours

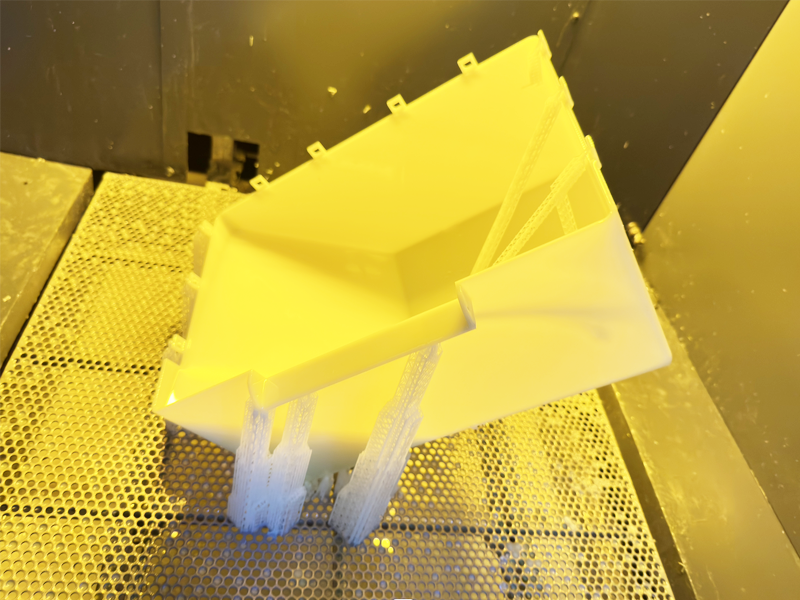

- SLA, SLS, SLM et FDM

- Accrédité ISO9001:2015 et ISO13485

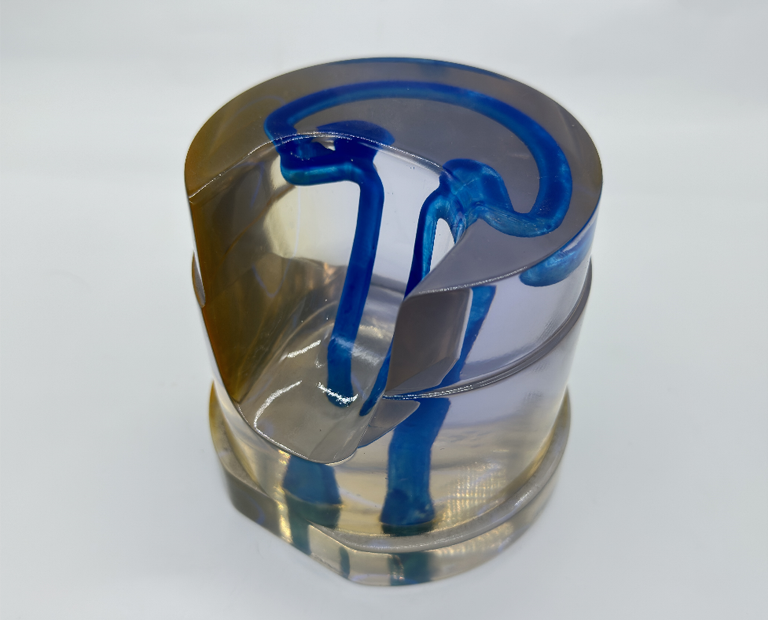

Découvrez le summum de la fabrication additive avec l'impression 3D SLA, réputée pour sa précision et sa qualité de surface inégalées. La technologie SLA excelle dans la production de modèles extrêmement détaillés et de prototypes visuellement saisissants, offrant une haute résolution et des surfaces parfaitement lisses, ce qui en fait le choix idéal pour les géométries complexes et complexes.

Lire la suite ->

L'impression 3D utilise principalement des matériaux thermoplastiques comme le PLA, l'ABS, le PETG et le TPU pour créer des objets en extrudant des filaments fondus couche par couche.

Lire la suite ->

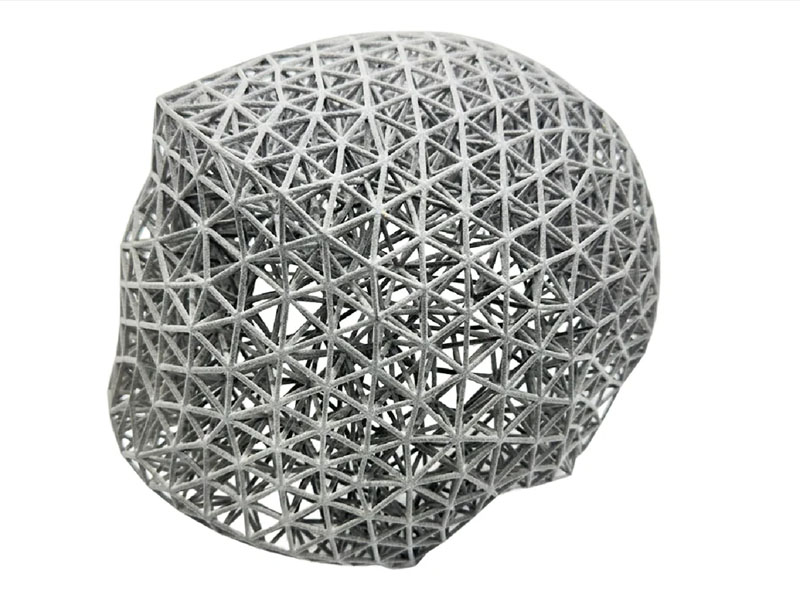

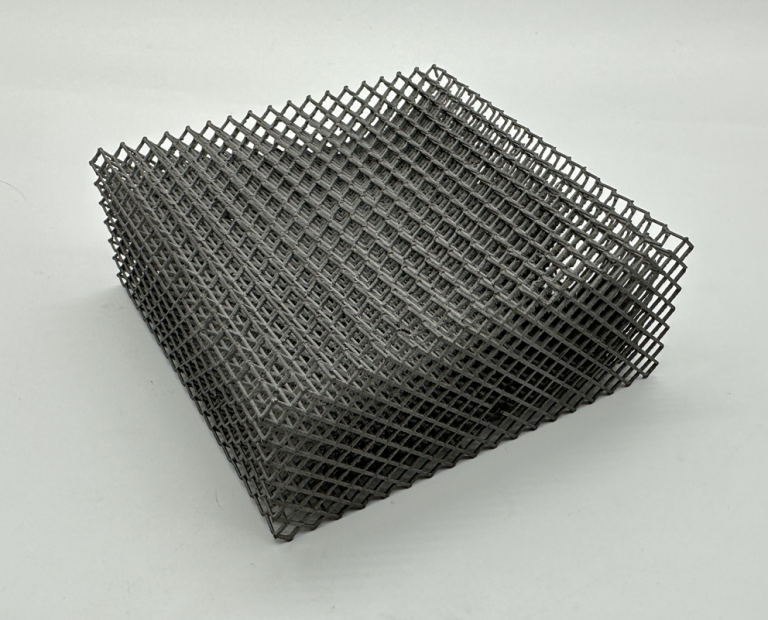

Révolutionnez votre processus de fabrication grâce à l'impression 3D SLM, où les poudres métalliques sont fusionnées pour former des pièces robustes et performantes. Idéale pour les industries aérospatiale et automobile, la technologie SLM permet d'obtenir des conceptions robustes et complexes avec des géométries complexes, garantissant durabilité et performances de premier ordre.

Lire la suite ->

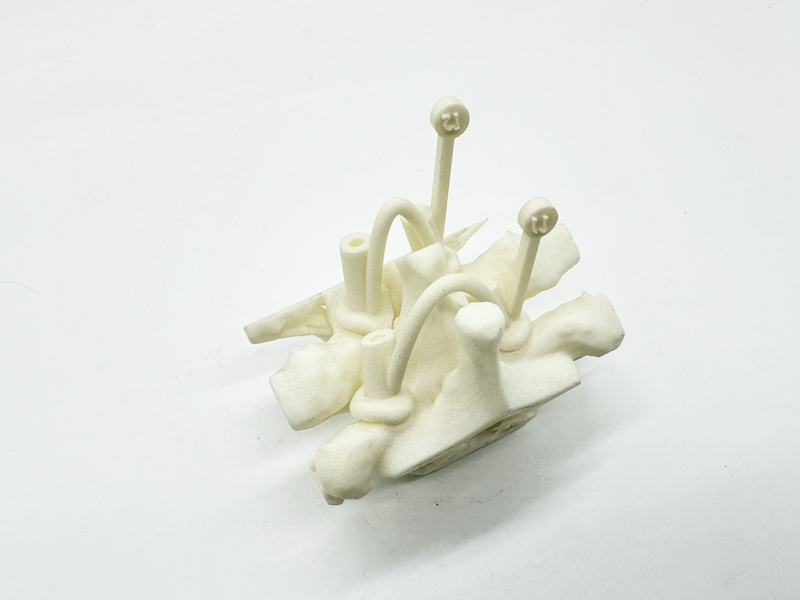

L'impression 3D SLS, reconnue pour sa robustesse et sa résilience, est un choix idéal pour la production de composants fonctionnels. Elle génère des impressions complexes et de qualité supérieure sans nécessiter de structures de support, offrant ainsi une plus grande flexibilité de conception.

Lire la suite ->

L'impression 3D avancée englobe plusieurs techniques de fabrication additive, chacune permettant de fabriquer des pièces couche par couche à partir d'un modèle 3D numérique. Alors que certaines machines extrudent des filaments pour former des pièces, d'autres utilisent des lasers pour fritter ou durcir des matériaux tels que des poudres métalliques ou plastiques et des résines liquides. Ces diverses technologies d'impression 3D varient en termes de compatibilité des matériaux, de précision de la finition de surface, de rentabilité et de capacité de production, entre autres facteurs.

Si vous commencez tout juste à utiliser les services d’impression 3D, jetez un œil rapide à la plage de tolérance de chaque processus pour voir lequel correspond à vos besoins.

| Processus d'impression 3D | Taille maximale de la pièce (po) | Taille maximale de la pièce (mm) | Taille Fonctionnalité (po) | Taille Caractéristique (mm) | Tolérances (en) | Tolérances (mm) | Matériels | Applications | Prix |

|---|---|---|---|---|---|---|---|---|---|

| Impression 3D en métal | 9,6 x 9,6 x 13,0 | 244 x 244 x 330 | 1 | 25.4 | 0.003 | 0.076 | Aluminium, acier inoxydable, titane, inconel, cobalt-chrome | Aérospatiale, Automobile, Médical | Haut |

| Stéréolithographie (SLA) | 11,1 x 14,9 x 14,9 | 282 x 378 x 378 | 0.006 | 0.152 | ±0,002 | ±0,051 | ABS, Polycarbonate, Silicone | Prototypage, Médical, Dentaire | Moyen |

| Frittage sélectif par laser (SLS) | 29 x 25 x 21 | 737 x 635 x 533 | 0.0025 | 0.064 | 0.01 | 0.254 | Polypropylène, Nylons, TPU | Prototypage, pièces fonctionnelles | Moyen |

| Fusion multijet (MJF) | 19 x 19 x 17 | 483 x 483 x 432 | 0.03 | 0.762 | ±0,012 | ±0,305 | Nylons, élastomères | Prototypage, pièces de production | Moyen |

| PolyJet | 11,1 x 14,9 x 14,9 | 282 x 378 x 378 | 0.02 | 0.508 | ±0,005 | ±0,127 | ABS, polypropylène | Prototypage, conception de produits | Moyen |

| DLS en carbone | 19,3 x 15,4 x 7,9 | 490 x 391 x 201 | 0.012 | 0.305 | ±0,010 | ±0,254 | Bas nylon | Automobile, biens de consommation | Haut |

| Matériel | Description |

|---|---|

| ABS (acrylonitrile butadiène styrène) | La résine ABS est un solide blanc laiteux connu pour sa solidité et sa résilience. Sa densité est d'environ 1,04 à 1,06 g/cm3 et elle présente une forte résistance à la corrosion aux acides, aux alcalis et aux sels. Elle offre également une bonne stabilité dimensionnelle, une bonne résistance chimique et des propriétés d'isolation électrique. L'ABS est largement utilisé dans diverses industries en raison de sa large plage de températures et de sa facilité de fabrication. |

| Nylon | Le nylon est un thermoplastique polyvalent connu pour sa grande résistance, sa durabilité et sa résistance chimique. Il est couramment utilisé dans les applications nécessitant une résistance aux chocs, telles que les pièces automobiles et les composants mécaniques. Le nylon offre également une excellente résistance à l'usure et peut supporter des températures élevées, ce qui le rend adapté aux applications d'ingénierie. |

| Polycarbonate (PC) | Le polycarbonate est un thermoplastique transparent connu pour sa résistance exceptionnelle aux chocs et sa clarté optique. Il est couramment utilisé dans les applications nécessitant une transparence et une durabilité élevées, telles que les lunettes de sécurité, le verre pare-balles et les composants électroniques. Le polycarbonate offre également une bonne résistance à la chaleur et une bonne stabilité dimensionnelle. |

| Polypropylène (PP) | Le polypropylène est un thermoplastique léger connu pour sa résistance chimique élevée, sa rigidité et sa solidité. Il est couramment utilisé dans les applications nécessitant une résistance à l'humidité, aux produits chimiques et à la fatigue, telles que les contenants alimentaires, les matériaux d'emballage et les composants automobiles. Le polypropylène est également recyclable et offre de bonnes propriétés d'isolation thermique. |

| Silicone | Le silicone est un polymère souple et durable connu pour sa résistance à la chaleur, sa biocompatibilité et ses propriétés d'isolation électrique. Il est couramment utilisé dans les applications nécessitant une certaine flexibilité, telles que les joints, les garnitures, les appareils médicaux et les ustensiles de cuisine. Le silicone offre également une bonne résistance aux rayons UV, à l'ozone et aux intempéries, ce qui le rend adapté aux applications extérieures. |

| TPU (polyuréthane thermoplastique) | Le TPU est un élastomère thermoplastique polyvalent connu pour sa flexibilité, sa résilience et sa résistance à l'abrasion. Il est couramment utilisé dans les applications nécessitant des surfaces douces au toucher, telles que les chaussures, les articles de sport et les étuis de téléphone. Le TPU offre également une bonne résistance chimique et peut être facilement traité à l'aide de techniques de moulage par injection ou d'impression 3D. |

| Matériel | Description |

|---|---|

| Aluminium | L'aluminium est un métal léger et polyvalent connu pour son rapport résistance/poids élevé, sa résistance à la corrosion et sa conductivité thermique. Il est couramment utilisé dans diverses industries, notamment l'aérospatiale, l'automobile et l'électronique grand public, pour des applications telles que les composants d'aéronefs, les pièces automobiles et les boîtiers électroniques. Les alliages d'aluminium offrent différentes propriétés en fonction des éléments d'alliage et des processus de traitement thermique, ce qui les rend adaptés à une large gamme d'applications. |

| Chrome cobalt | Le cobalt-chrome, également connu sous le nom d'alliage cobalt-chrome, est un alliage métallique à haute résistance connu pour son excellente résistance à l'usure, à la corrosion et à la biocompatibilité. Il est couramment utilisé dans les applications médicales et dentaires, telles que les implants dentaires, les implants orthopédiques et les prothèses, en raison de sa compatibilité avec le corps humain et de sa capacité à résister aux environnements difficiles. Les alliages cobalt-chrome peuvent être usinés et polis pour obtenir des dimensions et des finitions de surface précises. |

| Inconel | L'Inconel est une famille de superalliages à base de nickel connus pour leur résistance aux températures élevées, leur résistance à l'oxydation et leurs excellentes propriétés mécaniques à des températures élevées. Ils sont couramment utilisés dans l'aérospatiale, les turbines à gaz et les industries de transformation chimique pour des applications telles que les composants de moteurs à réaction, les aubes de turbines à gaz et les échangeurs de chaleur. Les alliages Inconel présentent une résistance et une résistance à la corrosion exceptionnelles, ce qui les rend adaptés aux environnements extrêmes et aux applications exigeantes. |

| Acier inoxydable | L'acier inoxydable est un alliage polyvalent et résistant à la corrosion, connu pour sa grande résistance, sa durabilité et son attrait esthétique. Il est couramment utilisé dans diverses industries, notamment l'automobile, l'aérospatiale et la médecine, pour des applications telles que les composants structurels, les instruments chirurgicaux et les appareils de cuisine. Les alliages d'acier inoxydable offrent différentes nuances et finitions pour répondre à des exigences spécifiques, allant des aciers inoxydables austénitiques pour une résistance élevée à la corrosion aux aciers inoxydables martensitiques pour une dureté et une résistance à l'usure améliorées. |

| Titane | Le titane est un métal léger et solide, connu pour son rapport résistance/poids élevé, sa résistance à la corrosion et sa biocompatibilité. Il est couramment utilisé dans les industries aérospatiale, médicale et marine pour des applications telles que les composants d'aéronefs, les implants médicaux et les équipements marins. Les alliages de titane offrent d'excellentes propriétés mécaniques à haute température et peuvent résister aux environnements corrosifs, ce qui les rend idéaux pour les applications critiques où la durabilité et les performances sont essentielles. |

| Limites de taille nominale | Métaux (ISO 2768-F) | Plastiques (ISO 2768-M) | Bois (MDF, bois véritable) | Bois (MDF, bois véritable) |

|---|---|---|---|---|

| 0,5 mm à 3 mm | ±0,05 mm (±0,002") | ±0,1 mm (±0,004") | ±0,2 mm (±0,008") | ±0,2 mm (±0,009") |

| Plus de 3 mm à 6 mm | +0,05 mm (±0,002") | ±0,1 mm (±0,004") | ±0,3 mm (±0,012") | ±0,3 mm (±0,013") |

| Plus de 6 mm à 30 mm | ±0,1 mm (±0,004") | ±0,2 mm (±0,008") | ±0,5 mm (±0,020") | ±0,5 mm (±0,021") |

| De plus de 30 mm à 120 mm | +0,15 mm (±0,006") | ±0,3 mm (±0,012") | ±1 mm (±0,040") | ±1 mm (±0,041") |

| De plus de 120 mm à 400 mm | ±0,2 mm (±0,008") | ±0,5 mm (±0,020") | ±2 mm (±0,080") | ±2 mm (±0,081") |

| Plus de 400 mm à 1 000 mm | ±0,4 mm (±0,016") | ±0,8 mm (±0,032") | ±5 mm (±0,200") | ±5 mm (±0,201") |

| Plus de 1000 mm à 2000 mm | ±0,5 mm (±0,020") | ±1,2 mm (±0,048") | ±10 mm (±0,400") | ±10 mm (±0,401") |

| Inachevé | Des points, ou « pointes » debout, restent visibles sur le bas de la pièce à partir des restes de la structure de support. |

| Naturel | Les surfaces supportées sont poncées pour éliminer les pointes de support. |

| Standard | Les surfaces supportées sont poncées et la pièce entière est finement sablée pour un aspect uniforme. Notez que les couches sont toujours présentes. |

| Coutume | Des peintures douces au toucher, des finitions de pièces transparentes, des peintures, des masquages, des correspondances de couleurs, des décalcomanies/graphiques et des finitions texturées sont disponibles. |

Vous souhaitez améliorer la résistance, la clarté ou l'apparence de vos pièces imprimées en 3D ? Faites votre choix parmi les matériaux microfluidiques et à micro-résolution, le placage métallique, l'usinage secondaire et les finitions personnalisées telles que la peinture, le revêtement transparent et la décalcomanie.

| Couche transparente | Finition cosmétique transparente pouvant être appliquée sur des matériaux translucides/transparents de type ABS (WaterShed XC 11122) et translucides/transparents de type PC (Accura 60). |

| Peinture | Après avoir lissé la pièce par ponçage et polissage, les pièces peuvent être peintes avec une peinture de qualité automobile. Fournissez une couleur pantone avec votre demande de devis. Nous proposons également une peinture soft touch. |

| Placage | Le placage au nickel chimique peut être utilisé pour obtenir des pièces similaires à celles en aluminium moulé ou en magnésium. |

| Teinture | La teinture est une autre méthode permettant d'ajouter de la couleur aux impressions 3D. Il s'agit d'une option plus rapide avec une sélection de couleurs limitée, donc un choix plus économique que la peinture. |

| Décalcomanie | La décalcomanie peut être utilisée pour ajouter un logo ou d'autres graphiques afin d'améliorer l'esthétique ou la fonction. |

| Polissage | Nous pouvons polir des pièces pour obtenir une finition miroir. Si cela est nécessaire, nous vous demandons de fournir un dessin ou une image indiquant vos attentes en matière de finition. |

| Traitement thermique | Durcissez et renforcez les impressions 3D en métal avec plusieurs options de traitement thermique : traitement thermique NADCAP, pressage isostatique à chaud (HIP), recuit en solution et vieillissement. |

| Usinage | Impression 3D de métal à la machine pour obtenir une qualité de finition de surface exceptionnelle ou respecter des tolérances strictes. |

Étape 1

Téléchargez votre conception

Il ne faut que quelques secondes pour télécharger vos fichiers de conception dans le formulaire de devis. Nous évaluons au moins 3 devis de partenaires de confiance et vous proposons le meilleur prix dans un délai d'un jour ouvrable.

Étape 2

Étape 3

Étape 4

L'impression 3D, également connue sous le nom de fabrication additive, est un procédé qui permet de créer des objets tridimensionnels en superposant des matériaux les uns sur les autres à l'aide d'une imprimante contrôlée par ordinateur. Elle permet de produire des modèles complexes et personnalisés.

L'impression 3D consiste à créer un modèle physique ou un prototype à l'aide d'une machine qui construit le modèle couche par couche à partir d'un fichier CAO. Le processus utilise généralement du plastique fondu ou des matériaux en poudre qui sont fusionnés pour créer le modèle. Cette technologie permet de produire des conceptions complexes et personnalisées avec une relative facilité et rapidité.

L'impression 3D peut être réalisée à partir de divers matériaux, notamment des plastiques (tels que l'ABS et le PLA), des métaux (comme l'acier inoxydable et le titane), des résines, des céramiques et même des matériaux de qualité alimentaire comme le chocolat.

Le temps d'impression d'un objet dépend de sa taille, de sa complexité et de la technologie d'impression 3D choisie. Les objets simples peuvent prendre quelques heures, tandis que les modèles plus grands ou complexes peuvent prendre plusieurs jours.

Les principes généraux de l'impression 3D impliquent la modélisation du design à l'aide d'un logiciel de CAO, le découpage du modèle en couches lisibles par l'imprimante, la fabrication des couches par dépôt de matériaux et la finition de l'objet imprimé. Les matériaux utilisés peuvent aller des polymères aux poudres métalliques, et le processus permet l'impression multi-matériaux et des avancées potentielles comme l'impression 4D.

L'impression 3D a une large gamme d'applications dans de nombreux secteurs, notamment :

L'impression 3D est utilisée à diverses fins, notamment le prototypage rapide, la fabrication de produits personnalisés ou sur mesure, la création de géométries complexes difficiles à produire à l'aide de méthodes traditionnelles, la production de modèles architecturaux, les applications médicales comme la création de prothèses et d'implants, et même l'impression d'aliments ou d'objets artistiques.

Rejoignez arapidprototype sur la voie vers un monde meilleur et plus rapide

et une innovation plus forte

Obtenez un devis maintenantTous les téléchargements sont sécurisés et confidentiels.