ARapidPrototype Laserschneidservice

Profitieren Sie von unseren außergewöhnlichen Fertigungskapazitäten und über 10 Jahren Branchenerfahrung bei ARapidPrototype. Wir bieten erstklassige, kundenspezifische Laserschneidservices mit unübertroffener Qualität und herausragendem Ergebnispotenzial. Unser Team aus hochqualifizierten Maschinisten nutzt modernste Laserschneidanlagen für die Bearbeitung einer breiten Materialpalette, von empfindlichen Aluminiumfolien bis hin zu dicken Stahlblechen. Entdecken Sie unseren Metall-Laserschneidservice mit fortschrittlichen Verfahren und Technologien für Ihre Projekte.

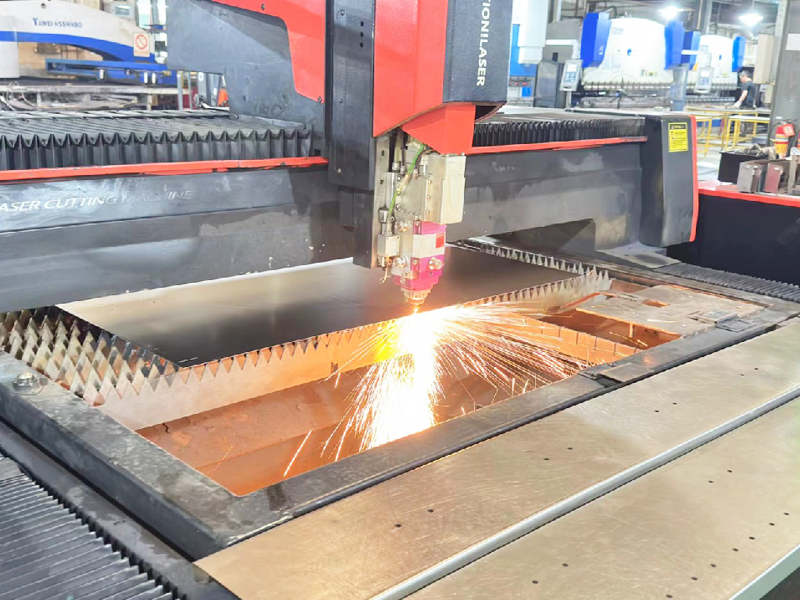

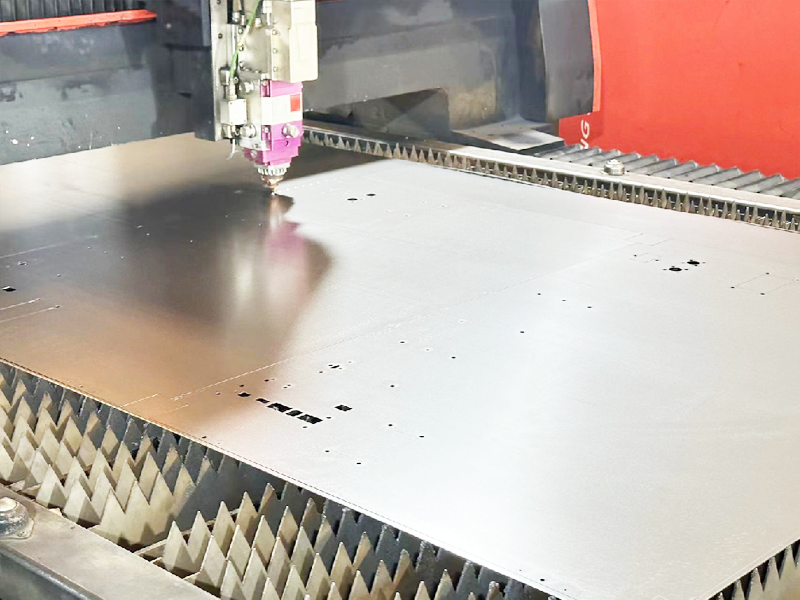

Faserlaserschneiden

Bei diesem Verfahren wird ein Faserlaser zum Schneiden eingesetzt. Dabei überträgt der Faserlaser den Laserstrahl über Glasfaser zum Schneidkopf, wo er auf die Werkstückoberfläche fokussiert wird, um mit hoher Energiedichte zu schneiden. Das Faserlaserschneiden zeichnet sich durch hohe Geschwindigkeit, Präzision, Effizienz und Vielseitigkeit bei verschiedenen Materialien aus und wird daher häufig in der industriellen Fertigung von Metallen, Nichtmetallen und Verbundwerkstoffen eingesetzt.

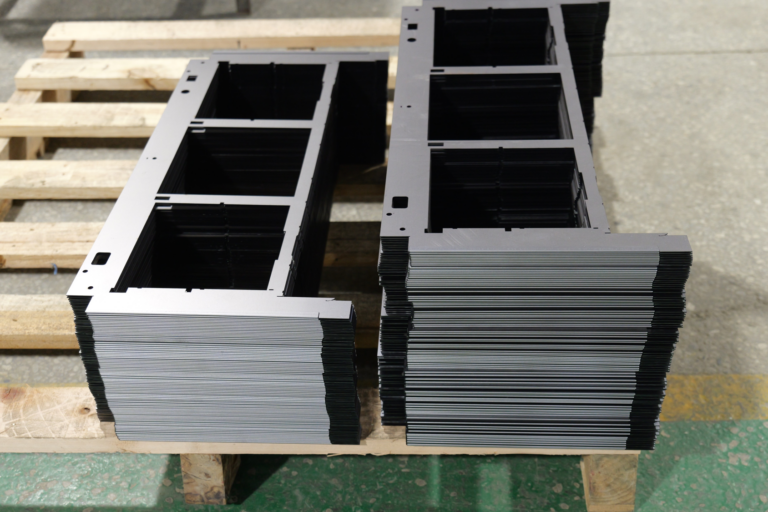

ARapidPrototype Laserschneidteile

Der Laserschneidservice von ARapidPrototype deckt seit vielen Jahren ein breites Anwendungsspektrum in zahlreichen Branchen ab. Nachfolgend finden Sie einige unserer bisherigen Laserschneidprojekte.

Designrichtlinien für Laserschneiden

Halten Sie diese Standards für flache, lasergeschnittene Komponenten ein, um die Qualität zu verbessern und die Produktionszeitpläne zu beschleunigen.

| Maximale Größe | 1220 x 2440 mm |

| Materialstärken | 1 mm bis 6 mm |

| Toleranzen | Plus oder minus 0,1 mm für normale Merkmale; Plus oder minus 0,05 mm für Einstecklöcher. |

Materialien und Dicken für lasergeschnittene Teile

Wir bieten die folgenden Metallmaterialien für kundenspezifische Laserschnittteile an. Beachten Sie, dass die maximale Teilegröße je nach Materialstärke variiert.

| Material | Grad | Verfügbare Stärken |

| Aluminium |

| 0,025 Zoll – 0,250 Zoll (0,635 mm – 6,35 mm) |

| Stahl |

| 0,025 Zoll – 0,250 Zoll (0,635 mm – 6,35 mm) |

| Edelstahl |

| 0,025 Zoll – 0,250 Zoll (0,635 mm – 6,35 mm) |

| Kupfer |

| 0,025 Zoll – 0,125 Zoll (0,635 mm – 3,175) |

| Messing |

| 0,025 Zoll – 0,125 Zoll (0,635 mm – 3,175) |

Anwendungen für lasergeschnittene Teile

Das Laserschneiden von Teilen ist ein weit verbreitetes Fertigungsverfahren in Branchen wie der Energiespeicherung, Computerelektronik, Robotik und Luft- und Raumfahrt. Typische Komponenten, die mit diesem Verfahren hergestellt werden, umfassen:

- Flache Teile: Das Laserschneiden eignet sich zum Schneiden flacher Teile wie Bleche, Platten und Sockel.

- Geometrische Formen: Durch Laserschneiden können verschiedene geometrische Formen präzise geschnitten werden, darunter Rechtecke, Kreise, Ellipsen und Polygone.

- Löcher und Ausschnitte: Durch Laserschneiden können problemlos Löcher und Ausschnitte zum Verbinden oder Zusammenbauen von Teilen geschnitten werden.

- Gravieren und Markieren: Laserschneiden kann auch zum Gravieren oder Markieren der Oberfläche von Teilen zur Identifizierung, Rückverfolgbarkeit oder zu dekorativen Zwecken verwendet werden.

- Biegen und Falten: Während das Laserschneiden in erster Linie für flache Teile verwendet wird, können damit auch Teile vorgeschnitten werden, um sie anschließend in die gewünschten Formen zu biegen oder zu falten.

Schnelles Online-Angebot

Laden Sie einfach Ihre Konstruktionsdateien hoch und wählen Sie Material, Veredelungsoptionen und Lieferzeit aus. Erhalten Sie mit nur wenigen Klicks schnelle Angebote für Ihre Blechkomponenten.

Robuste Fertigungskapazität

Unsere inländischen Fabriken in China bieten umfassende Projektlösungen für Blechbearbeitung und verfügen über flexible Materialoptionen, vielfältige Oberflächenbearbeitungen und unbegrenzte Fertigungskapazitäten für Klein- und Großserienproduktionen.

Garantierte Qualität

Mit unserer ISO 9001:2015-zertifizierten Blechfertigung bieten wir auf Anfrage Material- und vollständige Maßprüfberichte an. Vertrauen Sie darauf, dass die Teile, die Sie von ARapidPrototype erhalten, Ihre Erwartungen übertreffen werden.

Unterstützung bei der Blechbearbeitung

Wir bieten Ihnen rund um die Uhr Online-Kundensupport für Ihre individuellen Blechkonstruktions- und Fertigungsprobleme. Dazu gehören individuelle Vorschläge, die Ihnen helfen, bereits in der frühen Entwurfsphase Kosten zu senken.

Der ARapidPrototype-Prozess

Schritt 1

Laden Sie Ihr Design hoch

Das Hochladen Ihrer Designdateien in das Angebotsformular dauert nur wenige Sekunden. Wir vergleichen mindestens 3 Angebote von vertrauenswürdigen Partnern und liefern Ihnen innerhalb eines Werktags den besten Preis.

Schritt 2

Schritt 3

Schritt 4

Häufig gestellte Fragen zum ARapidPrototype-Laserschneidservice

Unser Laserschneidverfahren eignet sich für eine Vielzahl von Materialien, darunter Eisen- und Nichteisenmetalle, Kunststoffe und andere Nichtmetalle. Wir können auch Materialien mit unterschiedlichen Gewichten, Dicken und mechanischen Eigenschaften schneiden.

Unser Laserschneidservice kann Material mit einer Präzision von +/- 0,002 Zoll und einer Positionsgenauigkeit von +/- 0,004 Zoll schneiden.

ARapidPrototype bietet unterschiedliche Dickenspezifikationen für verschiedene Laserschneidmaterialien. Die maximale Dicke für Edelstahl und Aluminium beträgt < 15 mm. Kohlenstoffstahl hingegen kann bis zu einer Dicke von 25 mm und Kupfer bis zu einer Dicke von weniger als 12,7 mm geschnitten werden.

Ja, unsere Experten verfügen über ausreichend Erfahrung und Kenntnisse im Bereich Lasergravur und -ätzung. Daher sind wir in der Lage, Ihnen qualitativ hochwertige Dienstleistungen anzubieten, die Ihren Anforderungen gerecht werden.

Ja, Sie können das Material mit den verschiedenen Biegetechniken von ARapidPrototype biegen. Ihre Flachprofilprofile bieten eine Biegetoleranz. Wir bieten Blechbiegetechniken wie V-Biegen, Rollbiegen, Rotationsbiegen, Wischbiegen usw. an. Die verwendete Technik hängt von Ihren spezifischen Anwendungen ab.

Begleiten Sie ARapidprototype auf dem Weg zu besseren, schnelleren

und stärkere Innovation

Jetzt Angebot einholenAlle Uploads sind sicher und vertraulich.