ARapidPrototype

SMT-Platzierungsvorrichtungsdienste

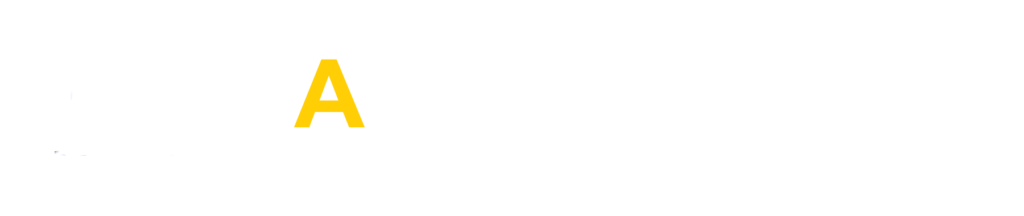

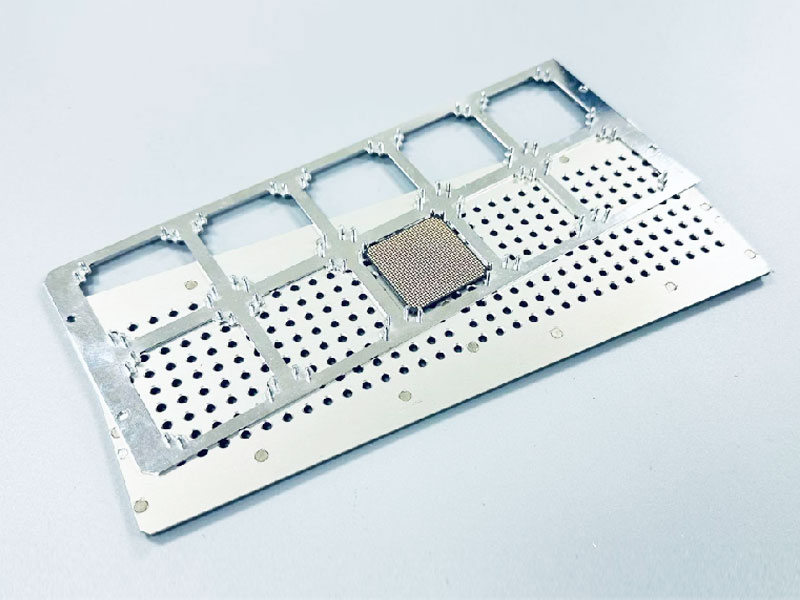

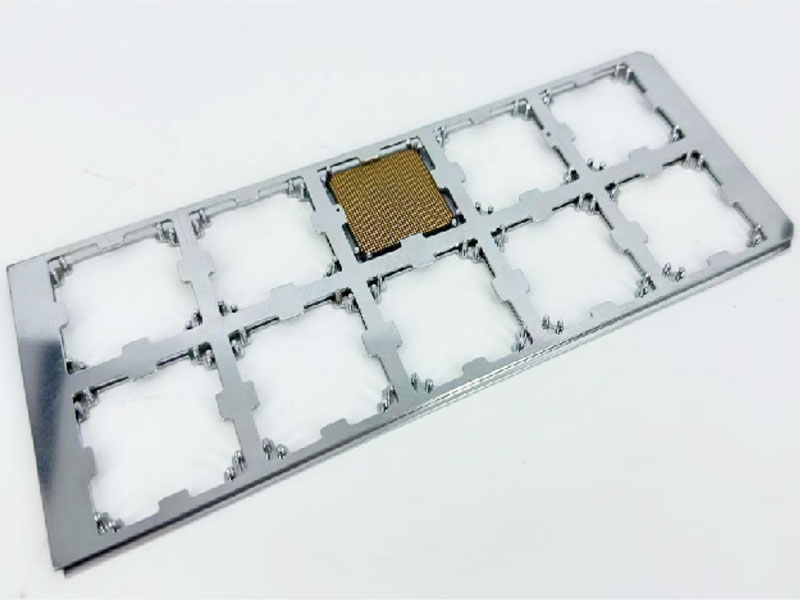

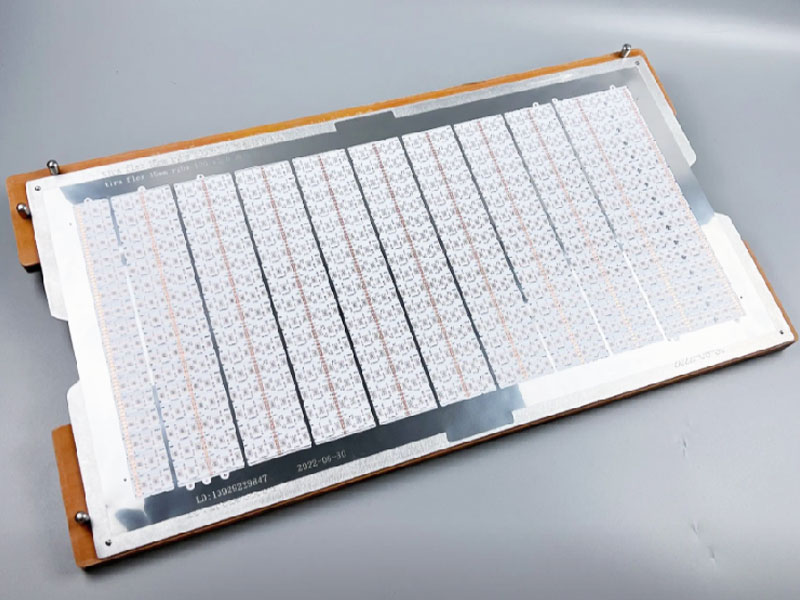

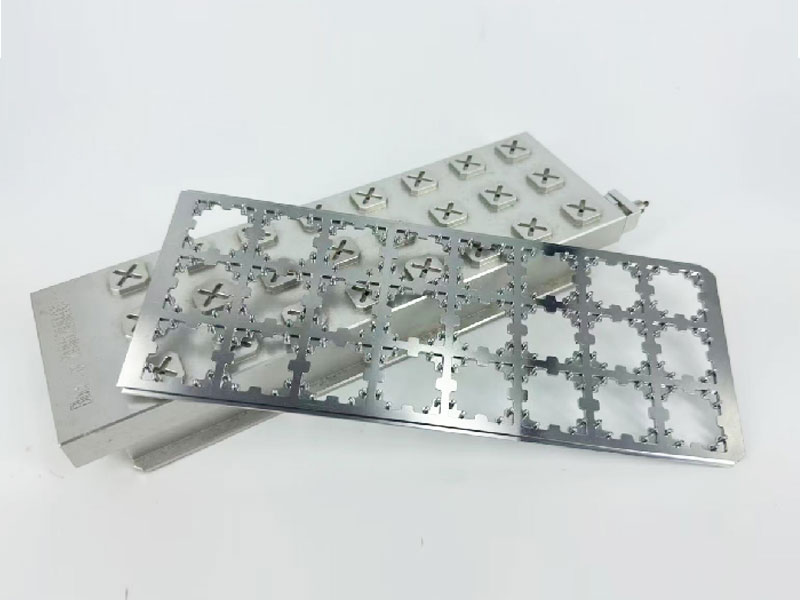

ARapidPrototype SMT-Vorrichtungen verfügen über eine große Druckfläche von 510 x 489 mm, beeindruckende Geschwindigkeiten bis zu 150 mm/sund hohe Genauigkeit von ±0,0125 mm. Sie sind für verschiedene Boardgrößen geeignet, von 40 x 50 mm bis 510 x 508 mm und Dicken von 0,2 mm bis 6,0 mm, was außergewöhnliche Flexibilität gewährleistet. Unsere Vorrichtungen verbessern die Produktionskonsistenz bei gleichzeitiger Kostenminimierung und bieten eine einzigartige, effiziente Lösung für Ihre Fertigungsanforderungen.