ARapidPrototype

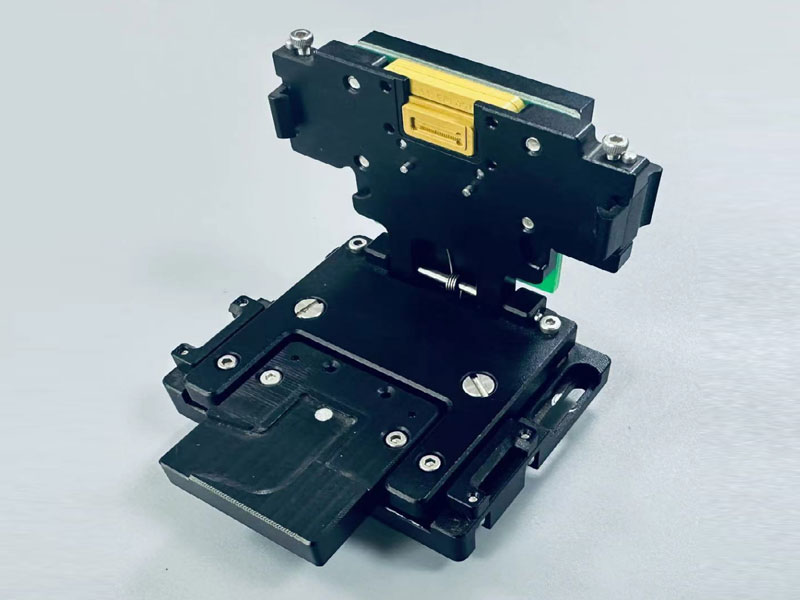

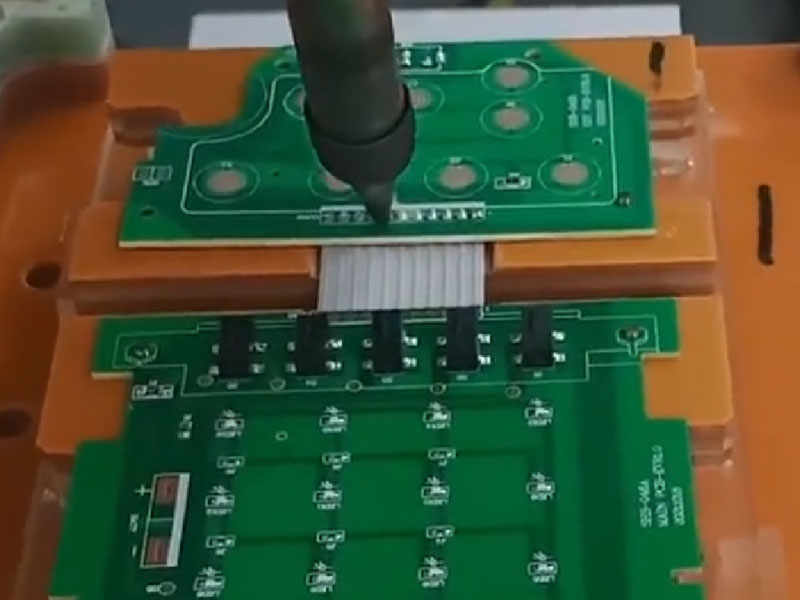

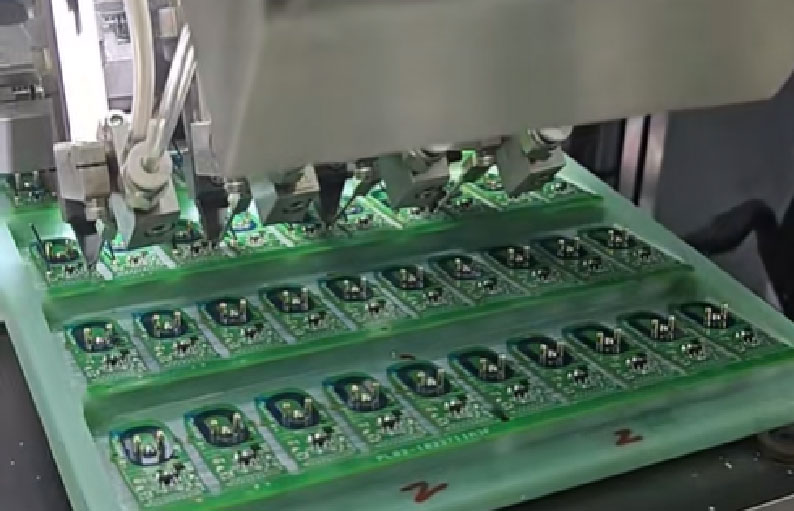

Dienstleistungen im Bereich Vorrichtungs- und Vorrichtungsherstellung

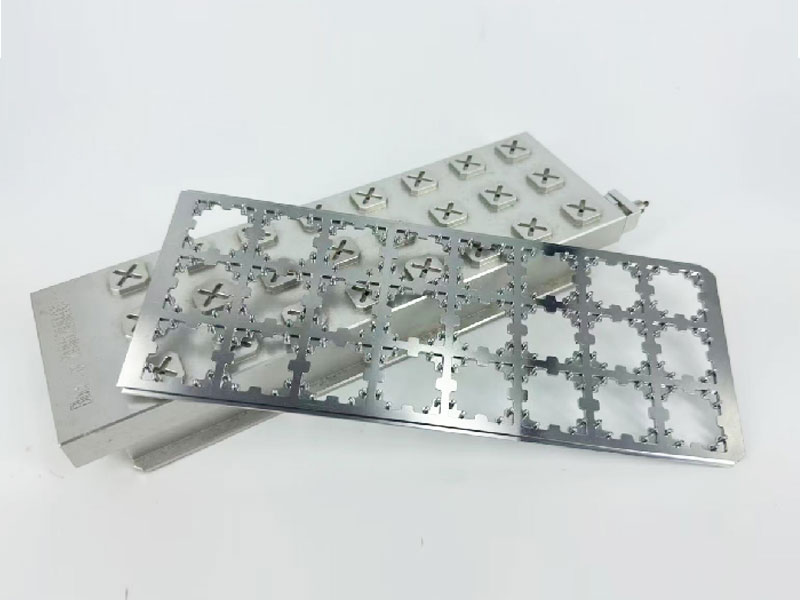

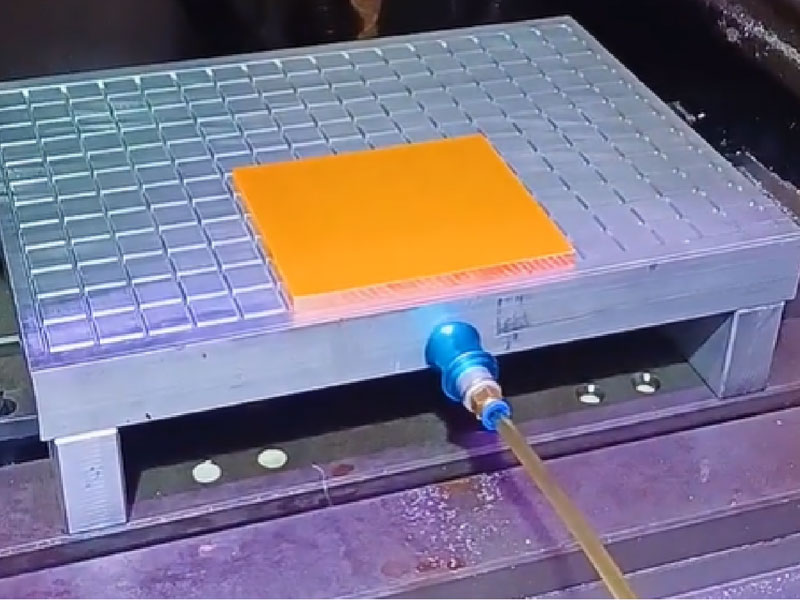

Wir bieten maßgeschneiderte Vorrichtungen für Ihre spezifischen Anforderungen. Sie vereinen branchenführendes Präzisionsdesign, außergewöhnliche Stabilität und optimierte Kosteneffizienz. Durch den Einsatz innovativer Materialien und Technologien steigern unsere Vorrichtungen nicht nur die Produktionseffizienz deutlich, sondern überzeugen auch durch unübertroffene Haltbarkeit und Zuverlässigkeit in komplexen Umgebungen. Diese einzigartigen Vorteile ermöglichen es uns, Lösungen anzubieten, die Branchenstandards übertreffen.