ARapidPrototype

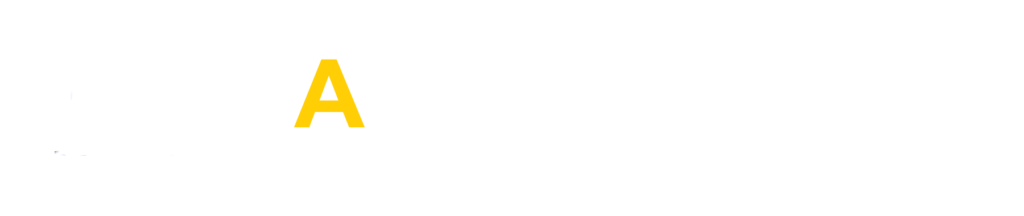

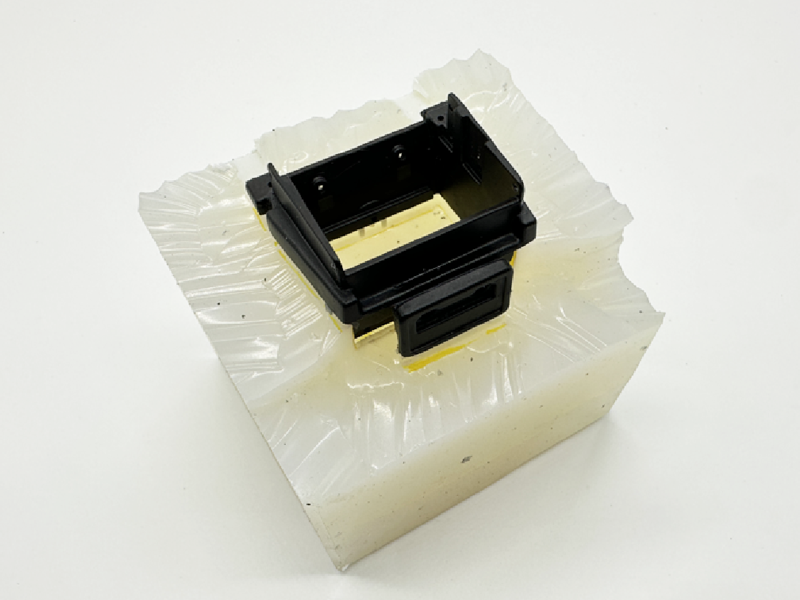

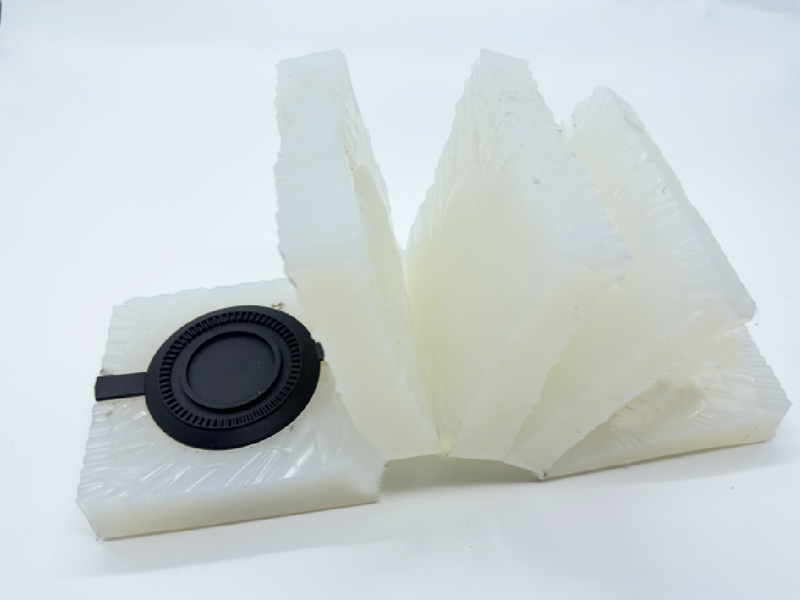

Vakuumguss-Dienstleistungen

Vermeidet Vorlaufzeit und Kosten für die Herstellung von Formen und erleichtert die Herstellung verschiedener Kunststoffteile, insbesondere die Kleinserienfertigung großer Teile.

Dekorationsteile: wie Kunsthandwerk, Souvenirs und Spielzeug.

Automobilteile: Prototypen und Kleinserienfertigung für den Innen- und Außenbereich von Autos, Kotflügel, Scheinwerferabdeckungen, Stoßstangenschützer und transparente Komponenten.

Elektronische Gehäuse: Prototypen für Telefongehäuse, Fernbedienungsgehäuse usw.