ARapidPrototype

Oberflächenveredelung

- Sandstrahlen

- Polieren

- Eloxieren

- Galvanisieren

- Spritzlackierung

- Siebdruck

- Lasergravur

- Einbrennfarbe

- Pulverbeschichtung

- Chemische Beschichtung

- Elektrophorese

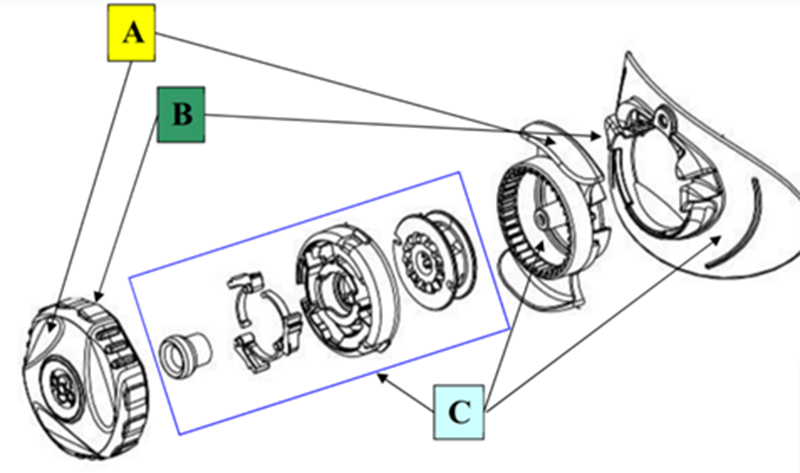

Optimierung der Qualitätskontrolle des Produktaussehens: Definieren der A-, B- und C-Seiten Bei Oberflächenveredelungsprozessen wie Eloxieren oder Pulverbeschichten können ästhetische Mängel wie Hängespuren auftreten. Um fehlerfreie Ergebnisse zu gewährleisten und gleichzeitig die Kosten unter Kontrolle zu halten, ist es wichtig, die A-, B- und C-Seiten in Ihrem Design zu definieren. In der folgenden Abbildung sehen Sie, wie Sie die A-, B- und C-Seiten in Ihren technischen Zeichnungen festlegen:

Erfahren Sie mehr über die Definition der A-, B- und C-Seiten, um den äußeren Qualitätskontrollprozess Ihres Produkts zu rationalisieren und die Ergebnisse zu optimieren.

| Primäre Oberfläche (A-Seite) | Sekundäroberfläche (B-Seite) | C-Seite | |

|---|---|---|---|

| Kratzer | NEIN | NEIN | NEIN |

| Flecken | NEIN | NEIN | NEIN |

| Schönheitsfehler | NEIN | NEIN | NEIN |

| Hängemarken | NEIN | Geringfügig (bis zu 2) | Nicht zutreffend |

| Andere kleinere Mängel | NEIN | Ja (Bis zu 2) | Nicht zutreffend |

| Qualitätsstandard | Garantiert fehlerfreie Produktion | Kleinere Mängel können vorhanden sein | Erfüllt normalerweise nur die Montage- und Funktionsanforderungen |

Für die Primäroberfläche (A-Seite) Ihres Teils garantieren wir eine fehlerfreie Produktion. Sekundäroberflächen (B-Seite) hingegen können Bearbeitungsspuren und andere kleinere Unvollkommenheiten aufweisen. Die Oberflächen der B-Seite sind jedoch, wie der Rest Ihres Teils, frei von Kratzern, Flecken und Schönheitsfehlern. Was die C-Seite betrifft, legen wir in der Regel Wert auf die Erfüllung der Montage- und Funktionsanforderungen, ohne spezifische Oberflächenqualitätsstandards festzulegen.

Nicht ästhetisch

Entdecken Sie unsere umfangreiche Galerie mit sorgfältig gefrästen Prototypen und von unseren geschätzten Kunden gefertigten Teilen.

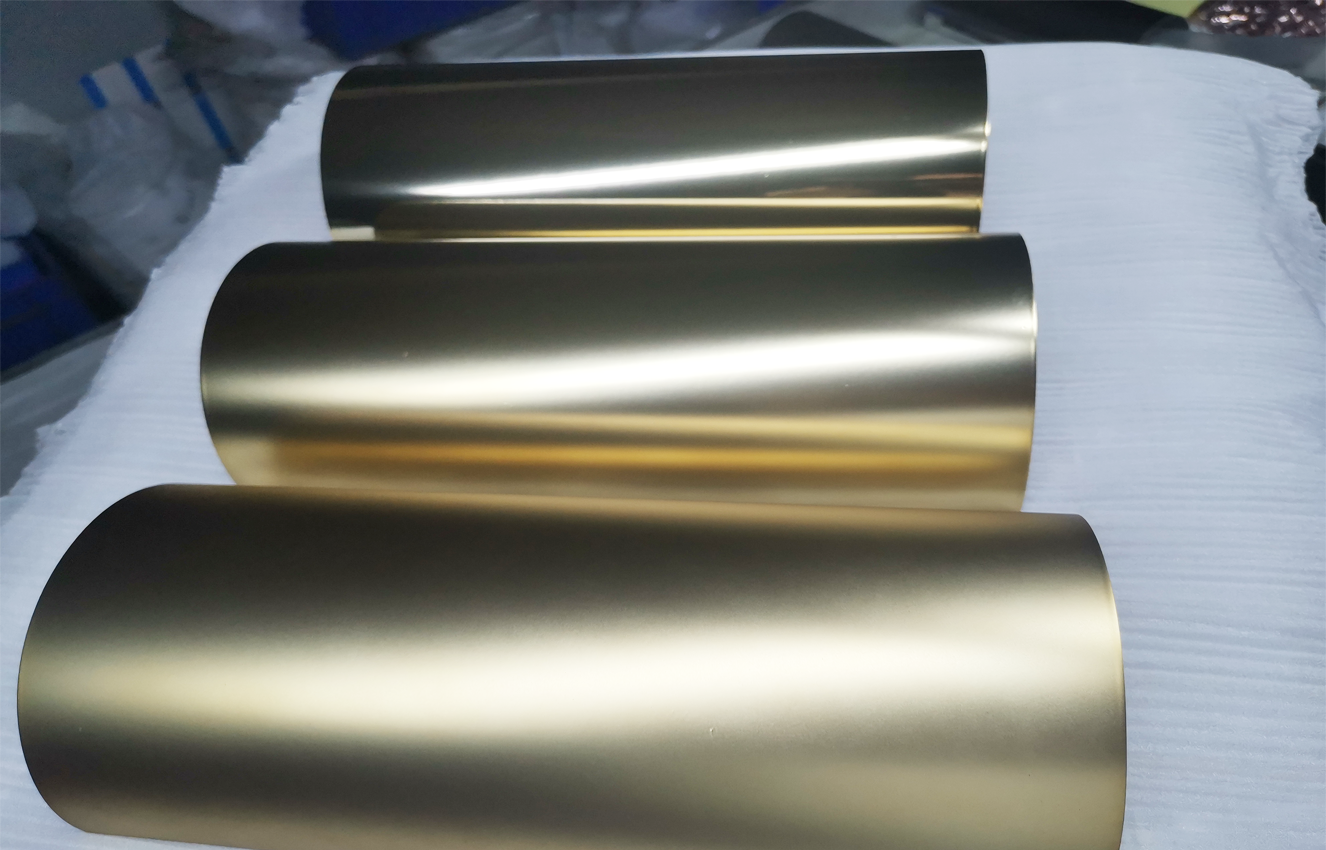

Oberflächenbehandlung P009 PVD Google Produktmaterialprüfung

| NAME DER VERARBEITUNG | SERVICE | Gültig für | BEARBEITUNGSSPUREN | KOSMETISCHE VERFÜGBARKEIT | TOLERANZEN |

|---|---|---|---|---|---|

| Wie bearbeitet | CNC-Bearbeitung, Blechbearbeitung | Metalle, Kunststoffe | Sichtbare, leichte Oberflächenkratzer | NEIN | Toleranzen werden nicht beeinflusst |

| Reibungslose Bearbeitung | CNC-Bearbeitung | Metalle, Kunststoffe | Sichtbare, leichte Oberflächenkratzer | NEIN | Toleranzen werden nicht beeinflusst |

| Feinbearbeitung | CNC-Bearbeitung | Metalle | Leicht sichtbar | NEIN | Toleranzen werden nicht beeinflusst |

| Polieren | CNC-Bearbeitung | Metalle | Auf Primärflächen entfernt | Immer kosmetisch | Nach dem Polieren erfüllt |

| Glasperlenstrahlen | CNC-Bearbeitung, Blechbearbeitung | Metalle | Entfernt für nicht-kosmetische Zwecke, entfernt auf primären Oberflächen für kosmetische Zwecke | Auf Anfrage | Nicht betroffen, außer für bestimmte Funktionen* |

| Bürsten | CNC-Bearbeitung, Blechbearbeitung | Metalle | Reduziert für nicht-kosmetische Zwecke, entfernt auf primären Oberflächen für kosmetische Zwecke | Auf Anfrage | Nach dem Bürsten getroffen |

| Eloxieren Typ II | CNC-Bearbeitung, Blechbearbeitung | Aluminium | Reduziert für nicht-kosmetische Zwecke, entfernt auf primären Oberflächen für kosmetische Zwecke | Auf Anfrage | Met nach dem Eloxieren |

| Anodisieren Typ III | CNC-Bearbeitung, Blechbearbeitung | Aluminium | Sichtbar unter der Eloxierung | NEIN | Met nach dem Eloxieren |

| Schwarzes Oxid | CNC-Bearbeitung, Blechbearbeitung | Kupfer, Edelstahl, legierter Stahl, Werkzeugstahl, Weichstahl | Sichtbar | NEIN | Met nach dem Beschichten |

| Chromat-Konversionsbeschichtung | CNC-Bearbeitung, Blechbearbeitung | Aluminium | Sichtbar | NEIN | Met nach dem Beschichten |

| Chemische Vernickelung | CNC-Bearbeitung | Weichstahl, Aluminium, Edelstahl | Reduziert, aber sichtbar | NEIN | Met nach chemischer Vernickelung |

| Pulverbeschichtung | CNC-Bearbeitung, Blechbearbeitung | Metalle | ENTFERNT | NEIN | Vor dem Pulverbeschichten MET |

| Gebürstet + Elektropoliert | CNC-Bearbeitung | Edelstahl | Auf Primärflächen entfernt | Immer kosmetisch | Met nach dem Elektropolieren |

| Dampfglättung | 3D-Druck | Kunststoffe | Die Oberfläche erhält ein glatteres, glänzenderes Aussehen | NEIN | Vor der Dampfglättung erfüllt |

Schritt 1

Laden Sie Ihr Design hoch

Das Hochladen Ihrer Designdateien in das Angebotsformular dauert nur wenige Sekunden. Wir vergleichen mindestens 3 Angebote von vertrauenswürdigen Partnern und liefern Ihnen innerhalb eines Werktags den besten Preis.

Schritt 2

Schritt 3

Schritt 4

Unter Blechbearbeitung versteht man den Prozess der Herstellung von Teilen, Komponenten und Strukturen aus Blech.

Bei der Blechbearbeitung kommen verschiedene Techniken zum Einsatz, beispielsweise Schneiden, Formen, Schweißen, Lackieren und Veredeln, um ein Endprodukt zu schaffen, das sowohl ästhetisch ansprechend als auch langlebig ist.

Die Blechbearbeitung findet Anwendung in verschiedenen Branchen, darunter Möbel, Industriemaschinen, Automobilbau, Luft- und Raumfahrt, medizinische Geräte und mehr. Sie wird oft bevorzugt, wenn genaue Größe und Form für eine nahtlose Integration in ein System entscheidend sind. Darüber hinaus eignet sie sich hervorragend für die Herstellung komplizierter Teile mit komplexen Details, wie Kühlventilatoren und Gehäuse.

Die Kosten für die Blechbearbeitung variieren je nach Komplexität und Größe des Projekts. Im Allgemeinen verursachen größere Projekte mit komplizierten Details höhere Kosten als kleinere, einfachere. Darüber hinaus können die Kosten durch zusätzliche Prozesse wie Lackieren und Veredeln steigen. Für einen genauen, auf Ihr Projekt zugeschnittenen Kostenvoranschlag empfiehlt es sich, einen Fachmann zu konsultieren.

Begleiten Sie arapidprototype auf dem Weg zu besseren, schnelleren

und stärkere Innovation

Jetzt Angebot einholenAlle Uploads sind sicher und vertraulich.