ARapidPrototype

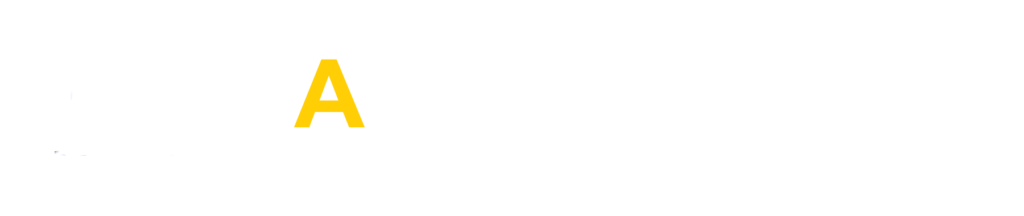

CNC-Fräsdienste

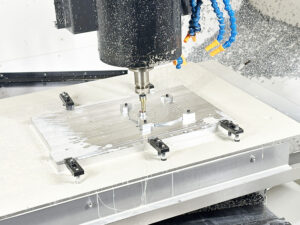

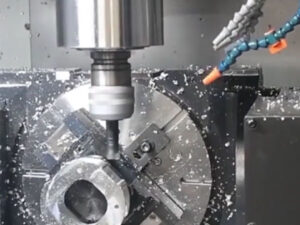

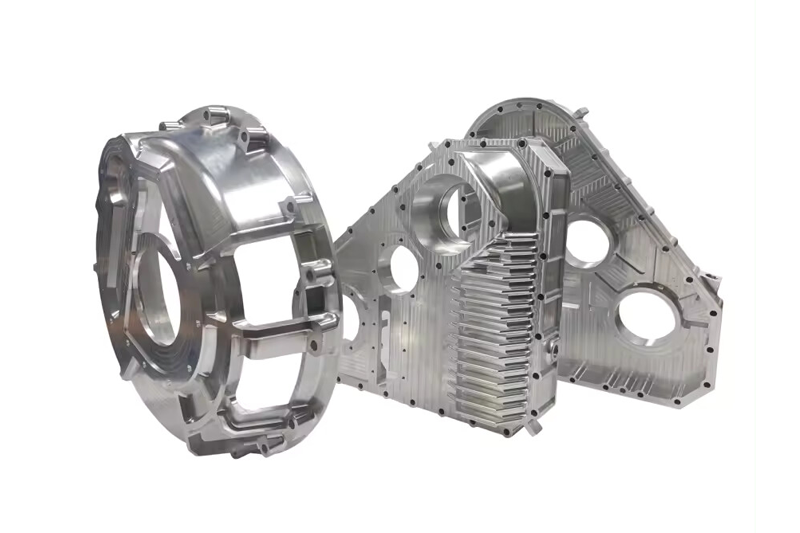

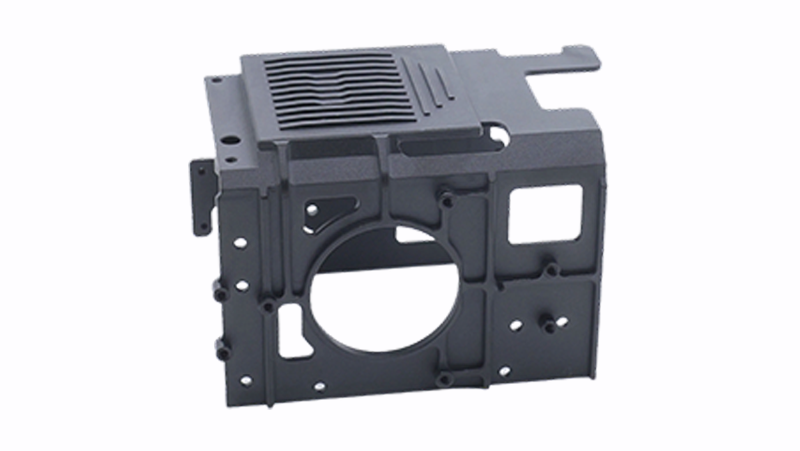

CNC-Fräsdienste liefern aufwendig gefertigte Komponenten mit außergewöhnlicher Präzision und Konsistenz, ideal für Prototypen, maßgeschneiderte Kreationen und groß angelegte Fertigungsprojekte.

- 3-, 4- und 5-achsige CNC-Fräsdienste gewährleisten Vielseitigkeit für unterschiedliche Anforderungen.

- Profitieren Sie von unseren schnellen Durchlaufzeiten, bei denen die Teile in nur 3 Tagen versandfertig sind. Egal, ob Sie Metall- oder Kunststoffbearbeitung benötigen, unsere Kapazitäten decken beide Materialien nahtlos ab.

- Erreichen Sie Toleranzen von bis zu +0,01 mm und garantieren Sie so eine beispiellose Genauigkeit für Ihre Projekte.