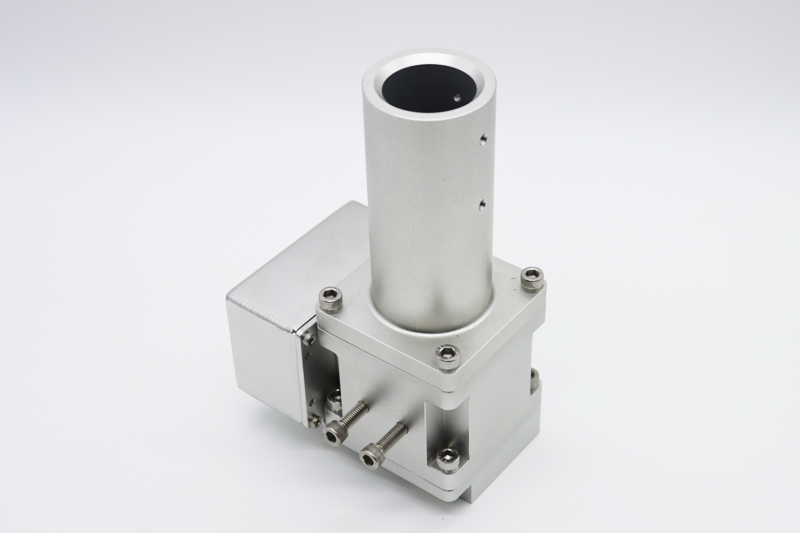

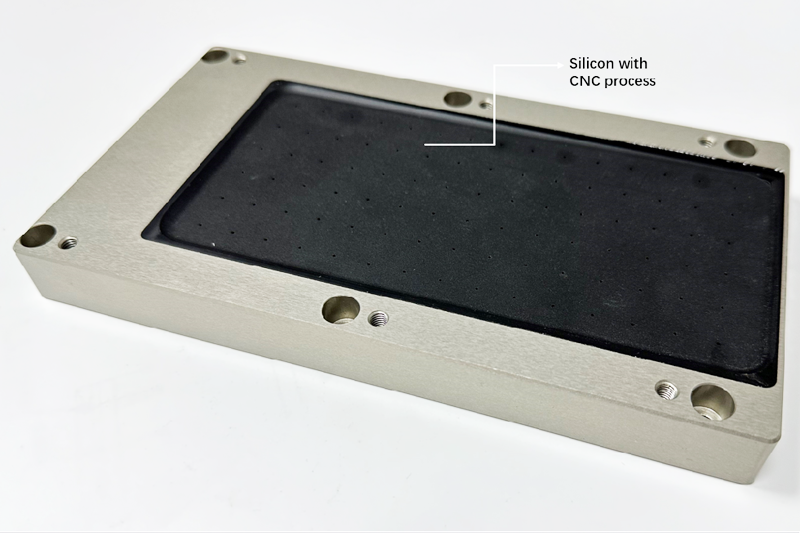

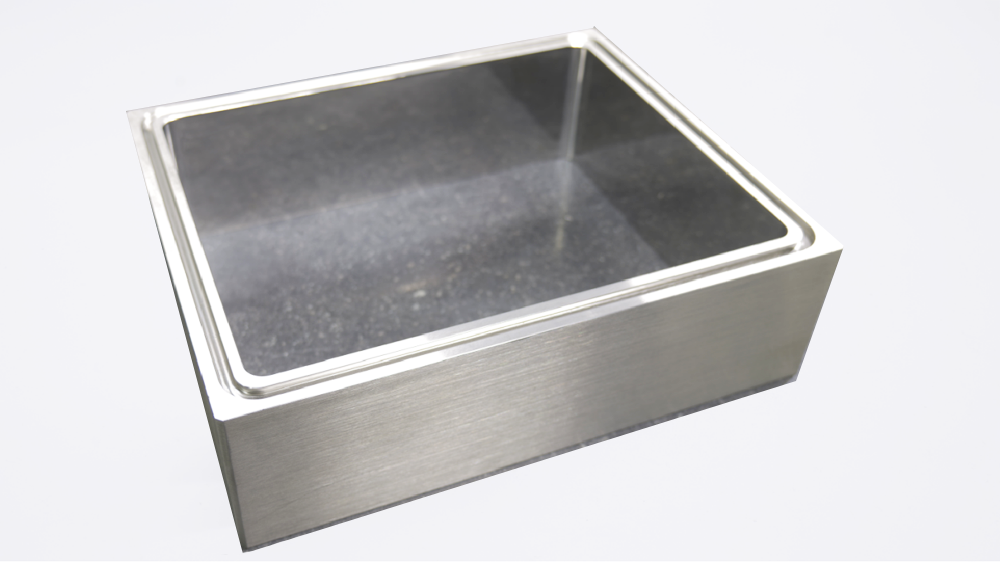

Edelstahl

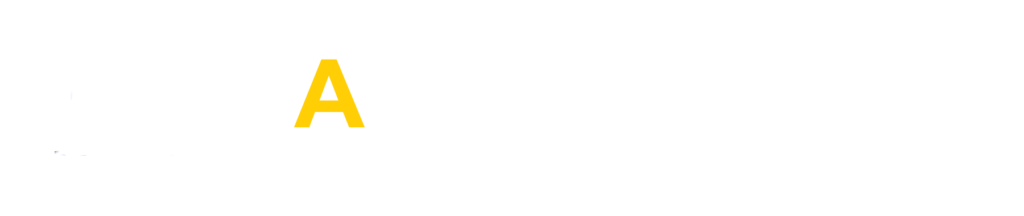

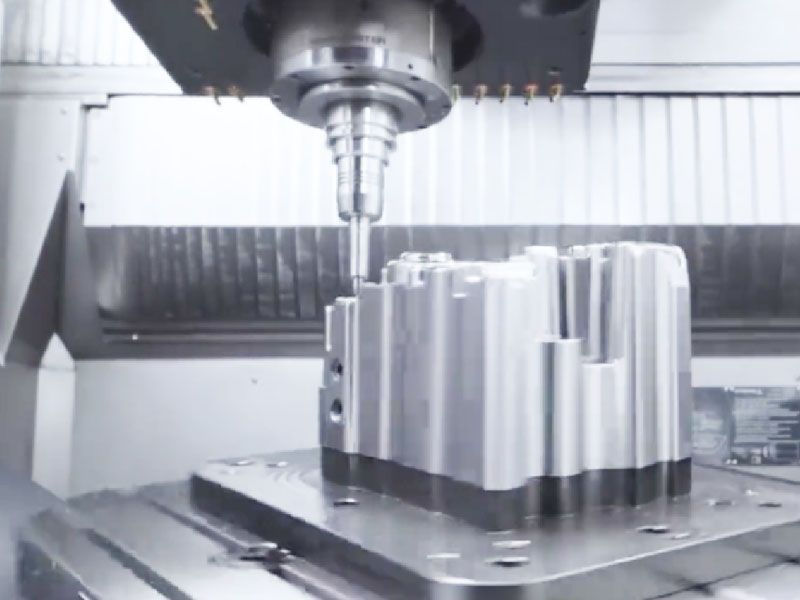

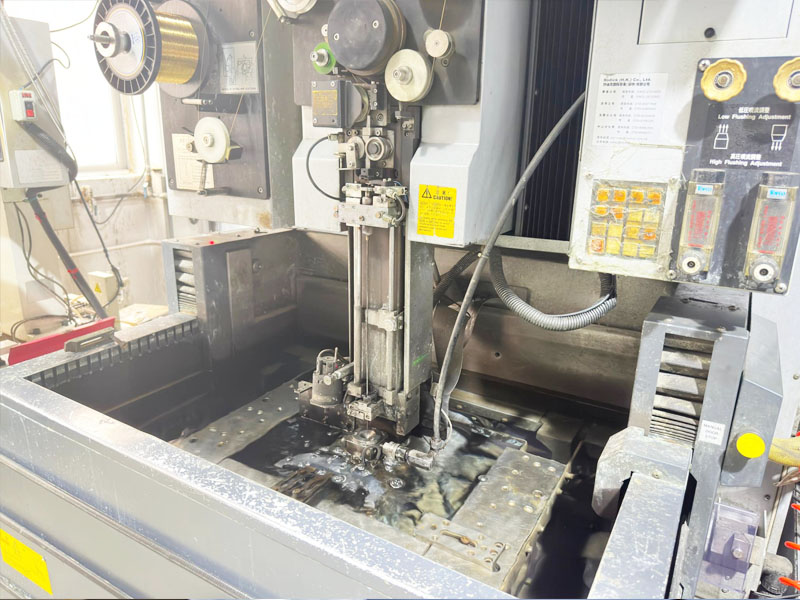

Edelstahl ist aufgrund seiner hohen Festigkeit und Haltbarkeit ein beliebtes Material für die CNC-Bearbeitung. Während des Bearbeitungsprozesses wird das Edelstahlmaterial mit verschiedenen Schneidwerkzeugen wie Bohrern, Fräsern und Drehmaschinen geschnitten, geformt und gebohrt.

Häufige Anwendungen:Luft- und Raumfahrt, Automobilindustrie, Medizin und Lebensmittelverarbeitung.