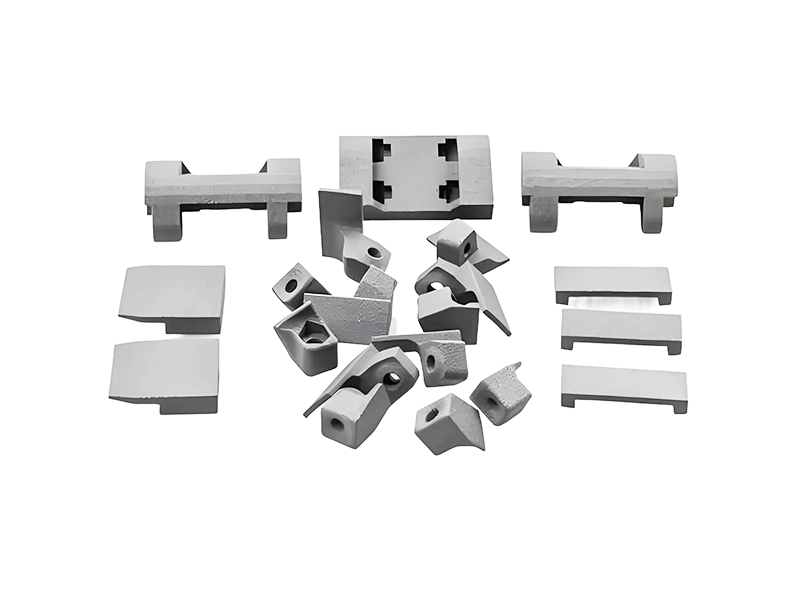

ARapidPrototype

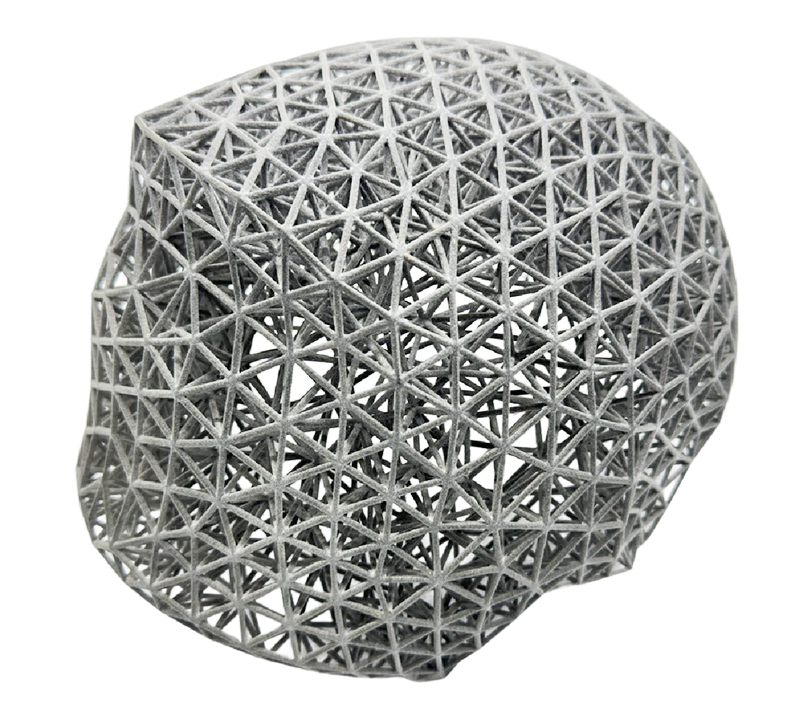

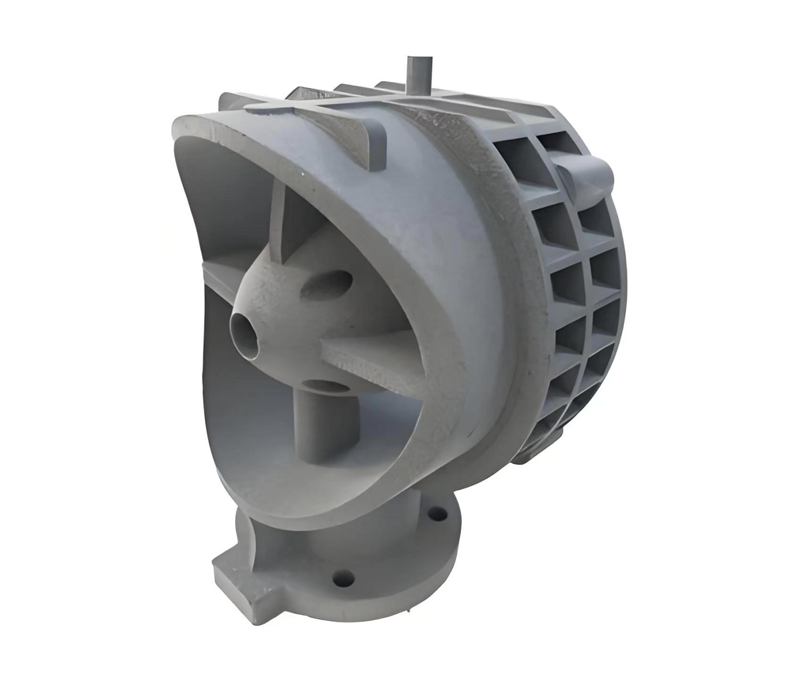

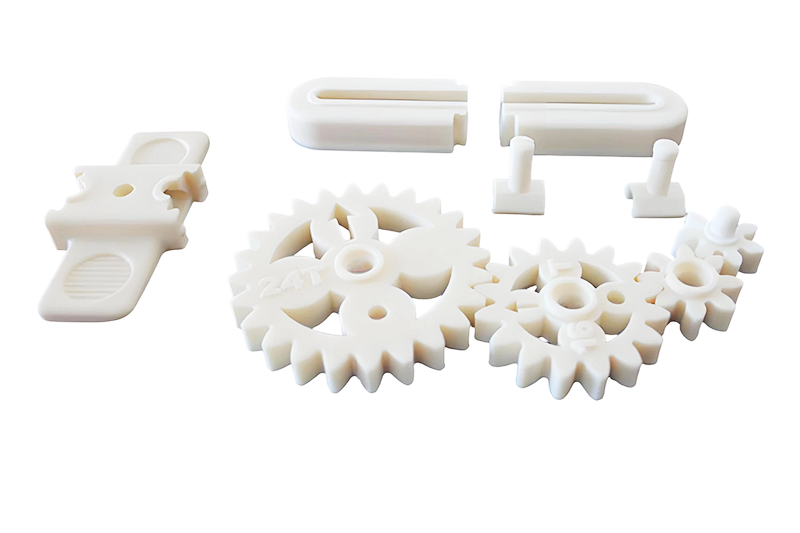

SLS 3D-Druckdienste

- Wählen Sie aus einer Vielzahl von Materialien in Industriequalität und umfangreichen Optionen für die Oberflächenveredelung.

- Profitieren Sie von einer Standardlieferzeit von nur 3 Werktagen für eine schnelle Lieferung.

- Ideal für die Herstellung von Vorrichtungen, Halterungen, Gehäusen, Schnappverschlüssen und Scharnieren