ARapidPrototype

Surface Finishing Services

- Sandblasting

- Polishing

- Anodizing

- Electroplating

- Spray Painting

- Silk Screening

- Laser Engraving

- Baking Paint

- Powder Coating

- Chemical Plating

- Electrophoresis

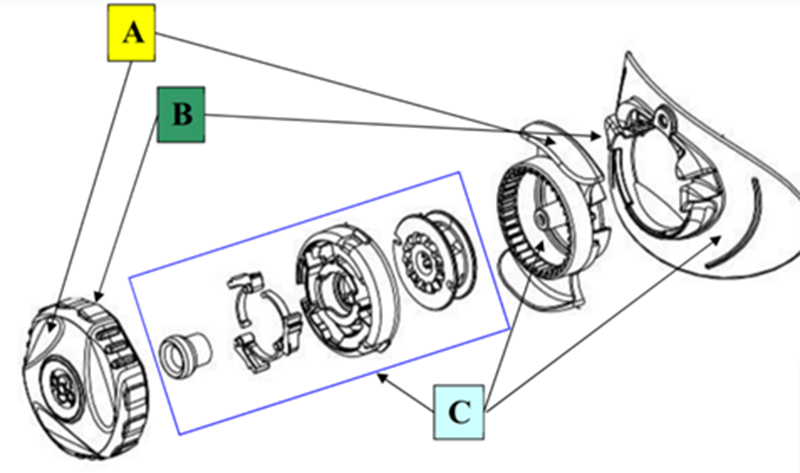

Optimizing Product Appearance Quality Control: Defining A, B, and C Sides During surface finishing processes like anodizing or powder coating, aesthetic imperfections such as hang marks can arise. To ensure defect-free results while keeping costs in check, it’s essential to define A, B, and C sides in your design. In the illustration below, you’ll see how to designate A, B, and C sides in your technical drawings:

Discover more about defining A, B, and C sides to streamline your product’s exterior quality control process and optimize results.

| Primary Surface (A-Side) | Secondary Surface (B-Side) | C-Side | |

|---|---|---|---|

| Scratches | No | No | No |

| Stains | No | No | No |

| Blemishes | No | No | No |

| Hanging marks | No | Minor (Up to 2) | Not Applicable |

| Other minor defects | No | Yes (Up to 2) | Not Applicable |

| Quality Standard | Defect-free production assured | Minor imperfections may be present | Typically meets assembly and functional requirements only |

For the primary surface (A-side) of your part, we assure defect-free production. Conversely, secondary surfaces (B-side) may exhibit machining marks and other minor imperfections. However, B-side surfaces, along with the rest of your part, will be devoid of scratches, stains, and blemishes. When it comes to the C-side, we typically prioritize meeting assembly and functional requirements, without imposing specific surface quality standards.

Non-Aesthetic

Explore our comprehensive gallery showcasing meticulously milled prototypes and parts crafted by our esteemed customers.

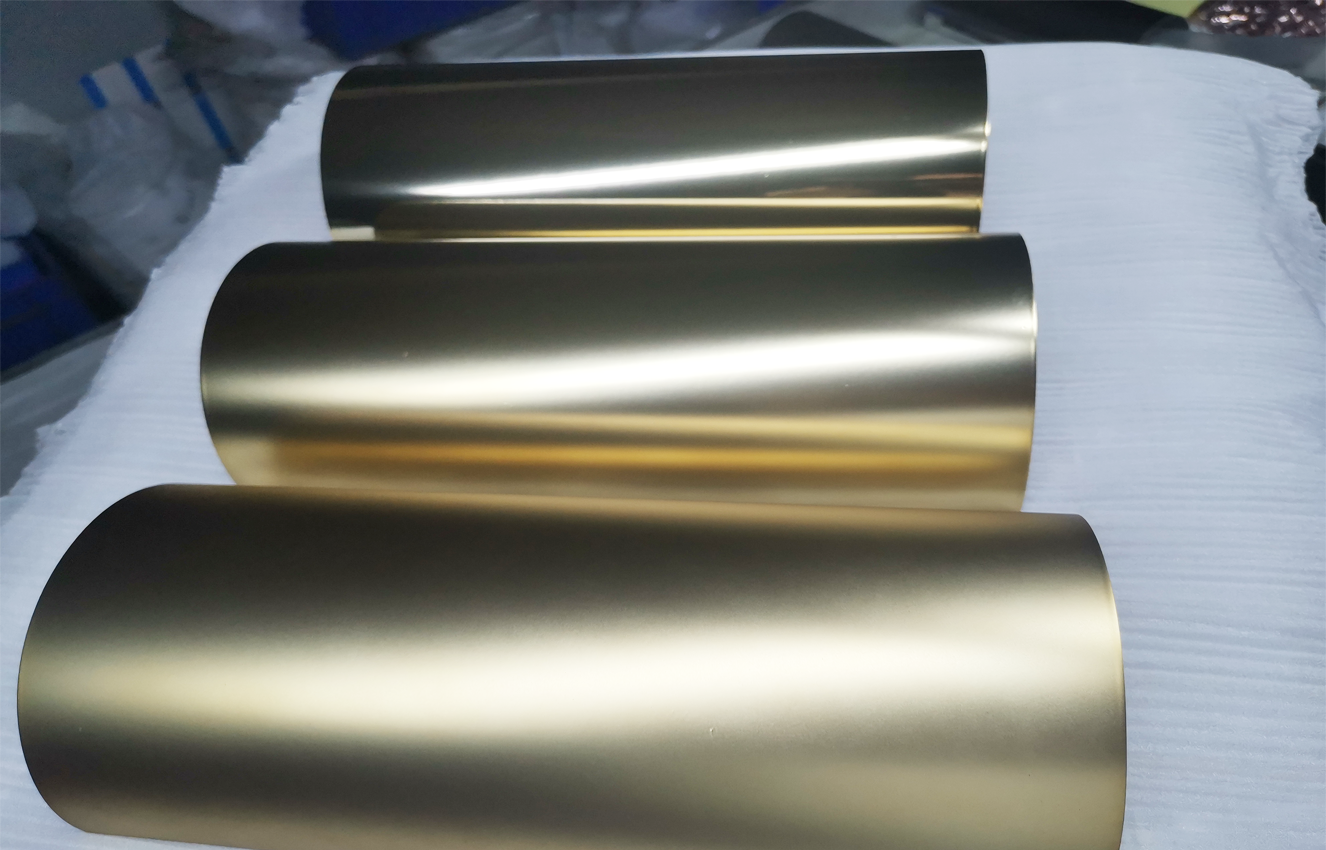

Surface treatment P009 PVD Google product material testing

| FINISHING NAME | SERVICE | APPLICABLE TO | MACHINING MARKS | COSMETIC AVAILABILITY | TOLERANCES |

|---|---|---|---|---|---|

| As machined | CNC machining, Sheet metal fabricat ion | Metals, Plastics | Visible, light surface scratches | No | Tolerances are not affected |

| Smooth machining | CNC machining | Metals, Plastics | Visible, light surface scratches | No | Tolerances are not affected |

| Fine machining | CNC machining | Metals | Slightly visible | No | Tolerances are not affected |

| Polishing | CNC machining | Metals | Removed on primary surfaces | Always cosmetic | Met after polishing |

| Bead blasting | CNC machining, Sheet metal fabrication | Metals | Removed for non-cosmetic, removed on primary surfaces for cosmetic | On request | Not affected except for specific features* |

| Brushing | CNC machining, Sheet metal fabrication | Metals | Reduced for non-cosmetic, removed on primary surfaces for cosmetic | On request | Met after brushing |

| Anodizing Type II | CNC machining, Sheet metal fabrication | Aluminum | Reduced for non-cosmetic, removed on primary surfaces for cosmetic | On request | Met after anodizing |

| Anodizing Type III | CNC machining, Sheet metal fabrication | Aluminum | Visible under anodizing | No | Met after anodizing |

| Black oxide | CNC machining, Sheet metal fabrication | Copper, Stainless steel, Alloy steel, Tool steel, Mild steel | Visible | No | Met after coating |

| Chromate conversion coating | CNC machining, Sheet metal fabrication | Aluminum | Visible | No | Met after coating |

| Electroless nickel plating | CNC machining | Mild steel, Aluminum, Stainless steel | Reduced but visible | No | Met after electroless nickel plating |

| Powder coating | CNC machining, Sheet metal fabrication | Metals | Removed | No | Met before powder coating |

| Brushed + electropolishing | CNC machining | Stainless steel | Removed on Primary surfaces | Always cosmetic | Met after electropolishing |

| Vapor smoothing | 3D printing | Plastics | Surface gets a smooth glossier appearance | No | Met before vapor smoothing |

Step 1

Upload Your Design

It takes just seconds to upload your design files to the quote form. We benchmark a minimum of 3 quotes from trusted partners and deliver you the best price within one business day.

Step 2

Step 3

Step 4

Sheet metal fabrication is the process of manufacturing parts, components, and structures from sheet metal.

Sheet metal fabrication involves various techniques such as cutting, forming, welding, painting, and finishing to create a final product that is both aesthetically pleasing and durable.

Sheet metal fabrication finds applications in diverse industries including furniture, industrial machinery, automotive, aerospace, medical equipment, and more. It is often preferred when precise size and shape are crucial for seamless integration within a system. Additionally, it excels in producing intricate parts with complex details, such as cooling fans and housings.

The cost of sheet metal fabrication varies depending on the complexity and size of the project. Generally, larger projects with intricate details incur higher costs compared to smaller, simpler ones. Additionally, expenses may increase with additional processes like painting and finishing. For an accurate cost estimate tailored to your project, consulting a professional is recommended.

Join arapidprototype on the path to better, faster

and stronger innovation

Get A Quote NowAll uploads are secure and confidential.