ARapidPrototype

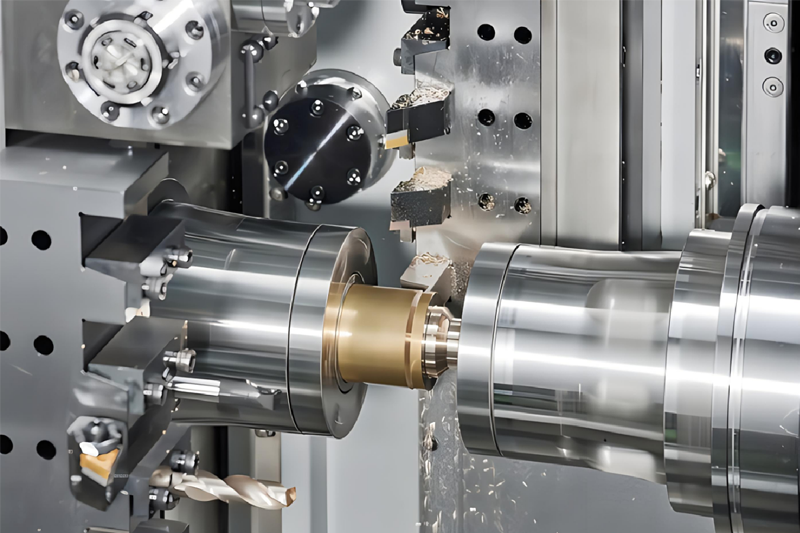

CNC Turning

- ServicesInstant Quotes Available.

- On-demand quote, even 1pcs.

- Ultra-Precise Tolerances of 0.02 mm.

- Rapid Turnaround Time, as Quick as 1 Day.

- Over a Decade of Manufacturing Expertise.

CNC turning is an essential manufacturing process that involves removing material from a rotating workpiece using precision cutting tools on a CNC lathe. At ARapidPrototype CNC turning center, we specialize in producing intricate and precisely dimensioned custom parts with our advanced CNC lathes. Whether you need metal or plastic components, our CNC turning services deliver high-quality results ideal for rapid prototyping or low-volume production.

| Material Category | Material Types |

|---|---|

| STAINLESS STEEL | 316L, 410, 304, 316, 401, 416, 420, 430, 440C |

| MILD, ALLOY & TOOL STEEL | Mild steel 1025, Mild steel 1008, Mild steel 1020, Mild steel 1018, Mild steel 1045 (#45), Alloy steel 1215, Alloy steel 4041, 40Cr steel, Alloy steel 4130, Alloy steel 4137, Alloy steel 4140, Alloy steel 4040 |

| OTHER COMMON METALS | Copper 101, Brass H62, Brass 260, Brass H59, Brass 385, Brass 360, Brass 2680, Bronze, Copper 110, Titanium TC2, Titanium TC4, Titanium TC5, Tool Steel A2, Tool Steel A3, Tool Steel D2 (Mould steel) |

| ALUMINUM | 5052, 6082, 6061-T651, 6063, 6061-T6, 6061, ADC12 (A380), 5083 |

| Material Type | Available Options |

|---|---|

| COMMOM PLASTIC | ABS, Polypropylene, Nylon 6, Delrin (POM-H), Acetal (POM-C) |

| REINFORCED PLASTIC | Garolite G-10, Polypropylene (PP) 30%GF, Nylon 30%GF, FR-4 |

| OTHER PLASTICS | PMMA (Acrylic), PVC, HDPE, UHMWPE, Polycarbonate, PET, PTFE (Teflon), Additional wood, rubber, etc. |

| Limits for Nominal Size | Metals (ISO 2768-F) | Plastics (ISO 2768-M) | Wood(MDF, Real wood) | Wood(MDF, Real wood) |

|---|---|---|---|---|

| 0.5mm to 3mm | ±0.05mm (±0.002") | ±0.1mm (±0.004") | ±0.2mm (±0.008") | ±0.2mm (±0.009") |

| Over 3mm to 6mm | +0.05mm (±0.002") | ±0.1mm (±0.004") | ±0.3mm (±0.012") | ±0.3mm (±0.013") |

| Over 6mm to 30mm | ±0.1mm (±0.004") | ±0.2mm (±0.008") | ±0.5mm (±0.020") | ±0.5mm (±0.021") |

| Over 30mm to 120mm | +0.15mm (±0.006") | ±0.3mm (±0.012") | ±1mm (±0.040") | ±1mm (±0.041") |

| Over 120mm to 400mm | ±0.2mm (±0.008") | ±0.5mm (±0.020") | ±2mm (±0.080") | ±2mm (±0.081") |

| Over 400mm to 1000mm | ±0.4mm (±0.016") | ±0.8mm (±0.032") | ±5mm (±0.200") | ±5mm (±0.201") |

| Over 1000mm to 2000mm | ±0.5mm (±0.020") | ±1.2mm (±0.048") | ±10mm (±0.400") | ±10mm (±0.401") |

Step 1

Upload Your Design

It takes just seconds to upload your design files to the quote form. We benchmark a minimum of 3 quotes from trusted partners and deliver you the best price within one business day.

Step 2

Step 3

Step 4

CNC milling and CNC turning are distinct machining processes with different operational methods, machinery, and applications.

Summary: CNC milling is best for parts with complex shapes and geometries, while CNC turning excels at producing cylindrical components. Both methods offer high precision, consistency, and efficiency.

CNC lathes and CNC turning centers perform different tasks. CNC lathes rotate a part to create circular shapes and can perform operations like facing, threading, knurling, drilling, reaming, and taper turning. Turning centers have advanced features that allow for more intricate pieces.

Join arapidprototype on the path to better, faster

and stronger innovation

Get A Quote NowAll uploads are secure and confidential.