ARapidPrototype

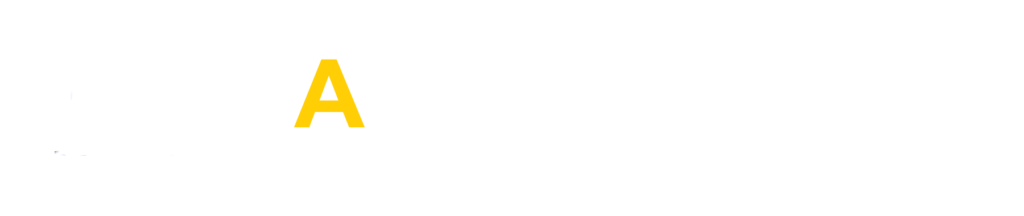

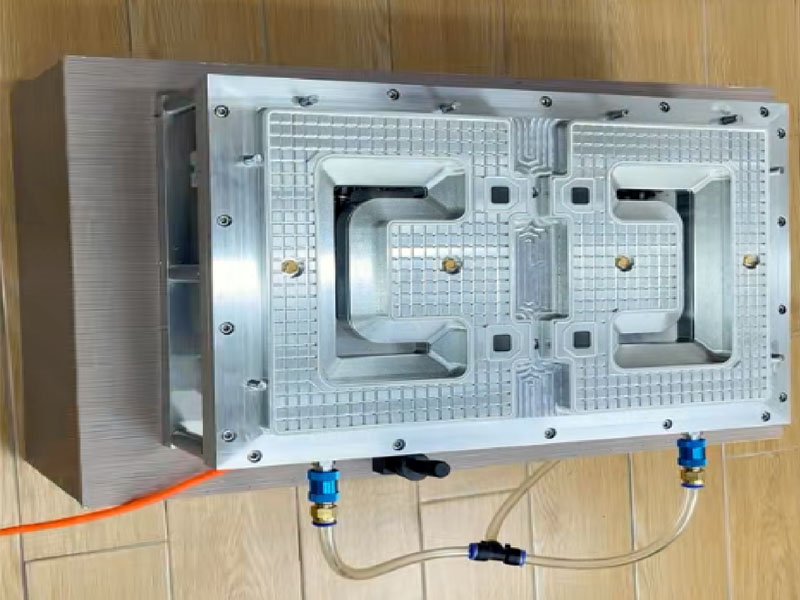

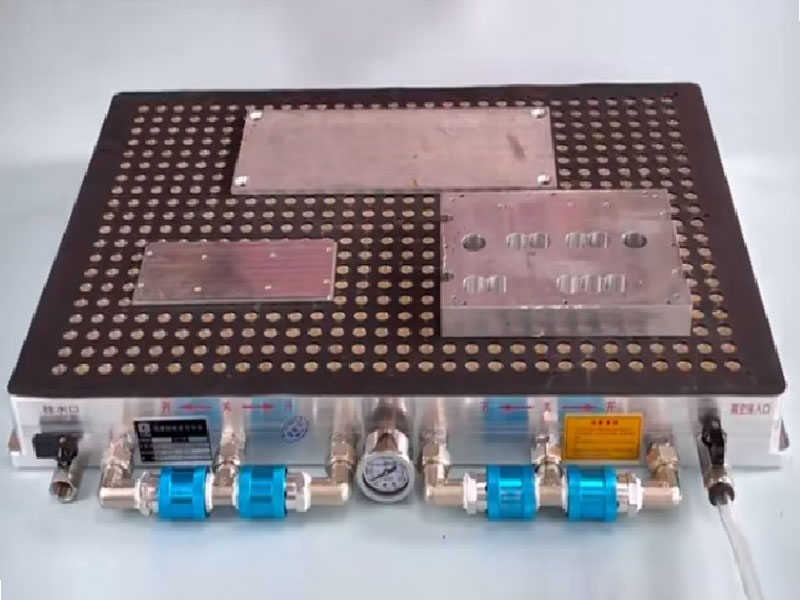

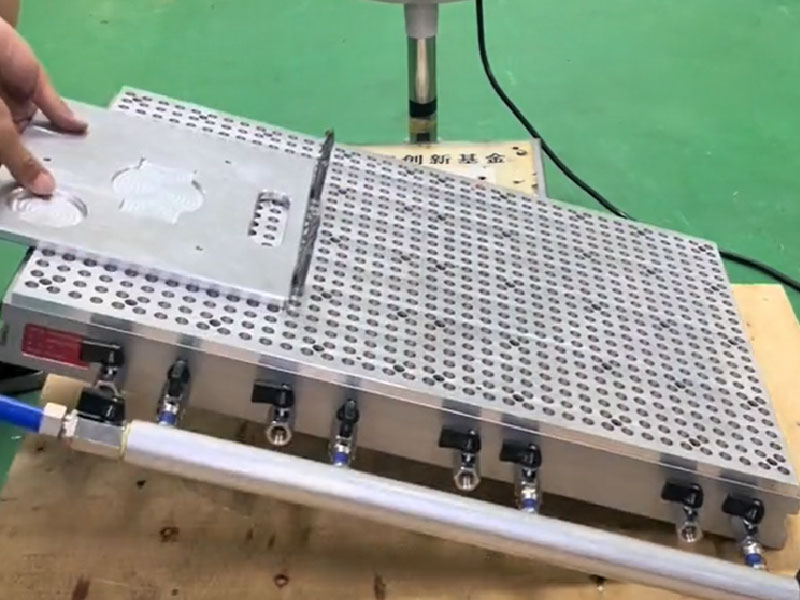

Vacuum Cup Fixtures

ARapidPrototype vacuum cup fixtures are engineered with advanced porous ceramic featuring 2 to 3-micron pores, delivering a powerful and stable vacuum while minimizing blockages. Available in ceramic, silicone, nitrile, and metal, our fixtures cater to diverse applications, from electronic assembly to precision machining. The fine ceramic pores ensure consistent vacuum force and exceptional durability. We also provide customizable solutions tailored to meet specific requirements, including high-temperature and chemical resistance, making our fixtures the ideal choice for any process.