ARapidPrototype

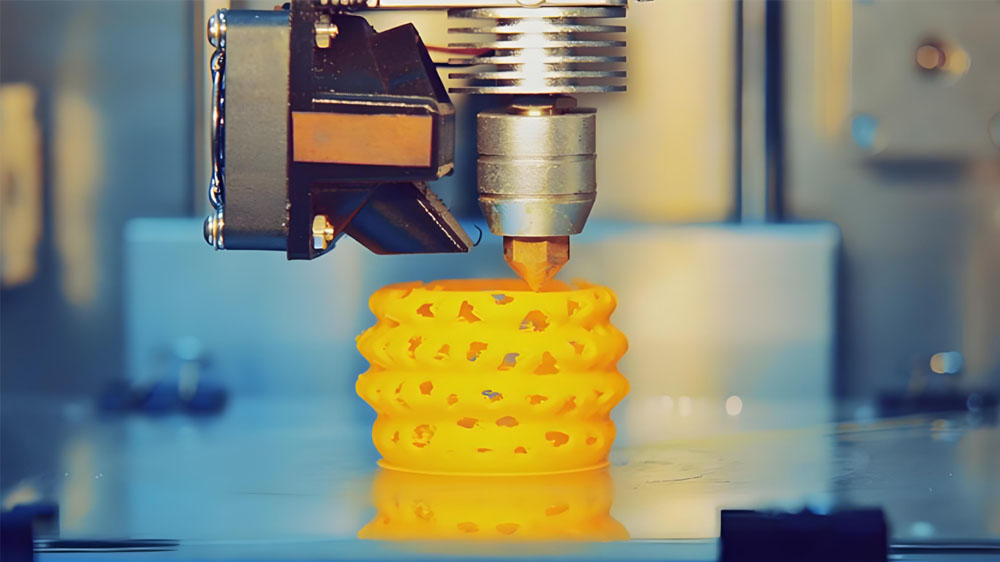

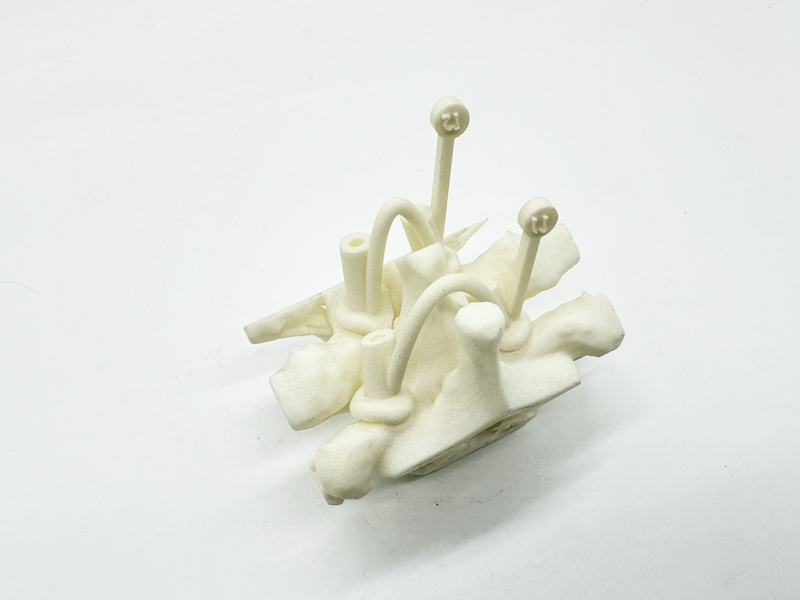

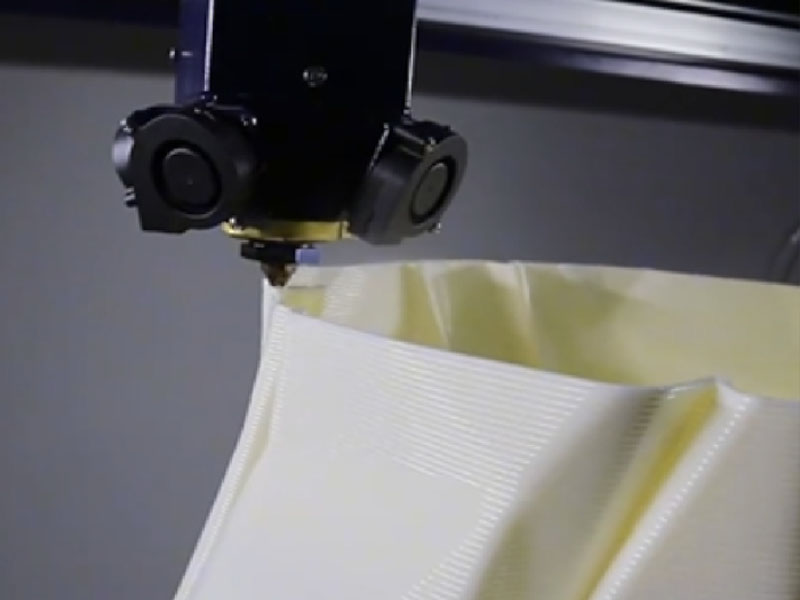

FDM 3D Printing Services

- Rapid Response Service: 7-day, 24-hour availability ensures quick project initiation, with urgent jobs starting immediately.

- Fast Turnaround: Parts completed in as little as 1 day, ideal for urgent needs.

- Cost Efficiency:Costs 10%-30% lower than competitors’, especially advantageous for complex projects.

- Comprehensive Surface Treatments: Offerings include a variety of treatments, supported by 30+ skilled workers.